ACMV-Manufactured Stone Veneer- The Next Big Problem in Construction

Updated for 2020! It’s been nearly five years since I wrote this series about the faulty installation of manufactured stone veneers, and the havoc it is causing unsuspecting homeowners. I decided it was time for some new information so I’ve updated things with new images and information.

It’s all the rage these days: Fake stone siding, manufactured stone veneer, stone veneer, cultured stone, or whatever you choose to call it. I personally stick with the term, manufactured stone, or just stone veneer for short.

The product is used as an accent on the front of a house (or it can be the whole siding in some cases). With it, you can give your home that mountain cabin look, right here in suburbia.

Manufactured Stone Veneer (or Adhered Concrete Masonry Veneer or Adhered Manufactured Stone Veneer, as it’s technically known) is a thin, man-made siding made to look like natural stones or rocks.

It’s basically molded concrete that looks like real stone.

Stone veneer is normally installed over the wood framing on a home. But when installed incorrectly, it will let water in next to your wood framing, trap it, and wreak havoc on the structure of the house. And so far, I’ve yet to see an install done correctly in Louisville, Kentucky (or anywhere for that matter).

LEAKING MANUFACTURED STONE VENEER CREATES MOISTURE PROBLEMS

In 2012, I was called in by a homeowner here in Louisville, Kentucky, to look at his 2-year-old custom-built home.

The family had tried to hang curtain rods on the front wall, and they discovered that their drywall was too wet and mushy to hold a plastic wall anchor.

They had no clue as to why things were wet. I was able to track the problem down to the manufactured stone veneer siding on the front of the house.

The builder had omitted all of the important flashing details with the install.

That day was the beginning of a 2-year fight between the homeowner and his builder. During that entire period, his dining room was blocked off and unusable because of the extensive wood rot and mold problems that came along with it.

The result: Attorneys were hired and things got ugly. The builder eventually repaired all of the water damage, stripped all of the manufactured stone off the home, and replaced it with real stone (they did not try to install manufactured stone again).

The final cost of the repair was close to $80,000.00.

Moisture intrusion experts have made a connection between manufactured stone veneer and traditional stucco (stucco homes in Louisville, Kentucky are very rare to find).

When problems arise from a botched install, a house with manufactured stone veneer shows the same moisture-related issues as a house with a botched stucco system. Water leaks behind the cladding and gets trapped. Then, the house rots.

In fact, one of the brightest minds in the world of building science, Dr. Joseph Lstiburek refers to manufactured stone veneer as “lumpy stucco.” He has a great article that you can read here: Stucco Woes.

Most manufacturers of ASMV are members of the Masonry Veneer Manufacturers Association or MVMA, who are now under the NCMA (National Concrete Masonry Association). I know, enough with the acronyms already.

The MVMA puts out an installation guide that is considered the “end-all-be-all” of how-to installation guides when it comes to manufactured stone veneer siding. When I am performing home inspections in Louisville KY, I refer to that guide and its details to show my clients how things should be done.

The problem is that I have never seen a home that has manufactured stone installed as the guide says it should be. Almost every detail is usually skipped–and we all know that the devil is in the details. You can download the MVMA guide here.

IDENTIFYING MANUFACTURED STONE VENEER

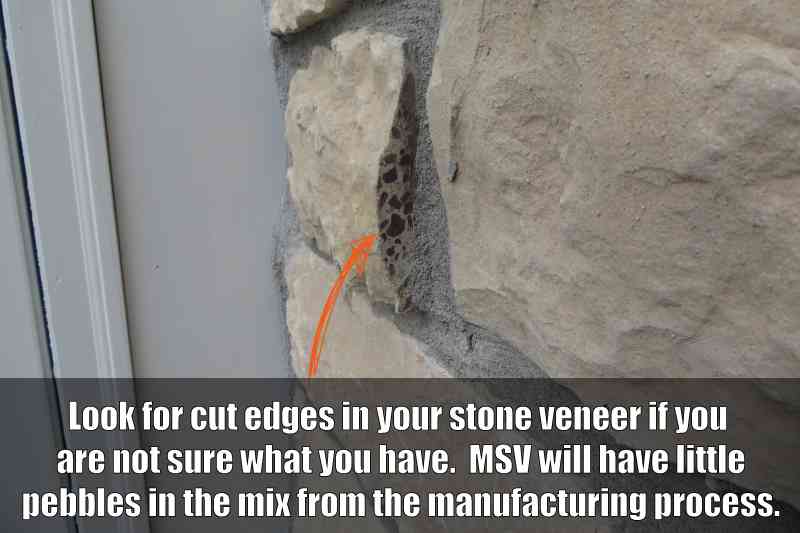

I’ve had a number of home inspectors and homeowners write to me over the years and ask, “Is this manufactured stone?” Let’s take a look at the ways you can determine if your cladding is manufactured stone.

Manufactured Stone Veneer Installs:

- Have cut edges on the stones. Most MSV installs will have at least a few stones that have been cut to fit into the wall. Look for those pieces. Usually, you can see the small pebbles in the casting from the manufacturing process. See the image below where I wet the edge to have the pebbles show up more clearly.

- Manufactured Stone Veneer will be stuck to the surface of the wall, hence the technical name of AMSV (Adhered Masonry Stone Veneer). You should be able to see the manufactured stone veneer pieces stop a few inches above the grade (soil or mulch). The reality though, is that it hardly ever does.

- Just about any building constructed in the past 30 years will use manufactured stone as opposed to real stone. It’s just too costly to use real stone or even real stone veneer. There are some exceptions, but generally, this rule holds true.

MOISTURE INFILTRATION WITH MANUFACTURED STONE VENEER

A wise man once told me that water and women can be lumped into the same category: They both always win.

Never is that statement more true than when it comes to the manufactured stone installation on your home. Water will find a way in.

It will seep in around the cracks, and it will be absorbed into the mortar and chunks of concrete. You didn’t think this stuff was waterproof, did you? It’s colored concrete. It absorbs the rainwater, the sprinkler water, melting snow–everything.

What we must do as construction professionals is design and build a wall system that can control the water and not let it reach the structural framing of the house. The moisture will get past the stone veneer; it’s what happens next that is vital to the integrity of your house.

Every type of siding (or cladding) needs to be able to drain the moisture that gets by it.

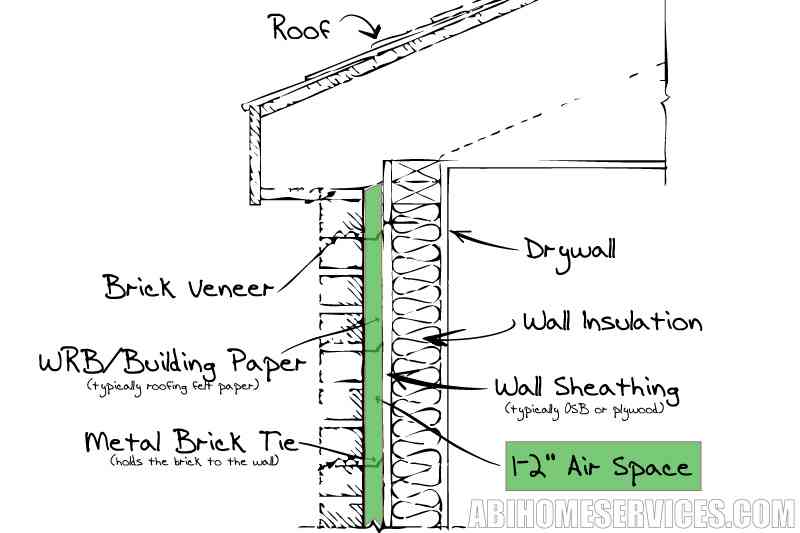

Take brick veneer for example. Building codes have required a 1″ gap (brick manufacturers recommend a 2″ gap, by the way) between the sheathing on a house and the backside of the brick.

When the water gets absorbed by the brick (No, brick veneer is not waterproof either), that gap is in place to make sure the water doesn’t soak the wood framing behind it. It gives the moisture a path to escape at the base of the wall, via weep holes.

Take a look at the brick wall detail below, and you’ll see the drainage plane present. The air gap is the green-colored area. This allows the moisture a path to escape, and more importantly, a decoupling of the brick and wood so that capillary action cannot draw the moisture into the wood framing.

I wrote an article about a home with a failed stone veneer and a failed brick weep system that caused catastrophic damage that you can read here (Failed Manufactured Stone and Brick Veneer on New Construction Home.) If you would like to see what the inside of a brick wall cavity looks like, you can get a general idea with this video I shot of a brick veneer wall assembly. Video of Brick Veneer Wall Assembly

FLASHING DETAILS MAKE OR BREAK MANUFACTURED STONE VENEER

Manufactured stone veneer is typically installed on top of the wood sheathing on a house. It doesn’t have an air gap since it’s adhered or stuck to the wall, and is not resting on the foundation wall (like brick veneer).

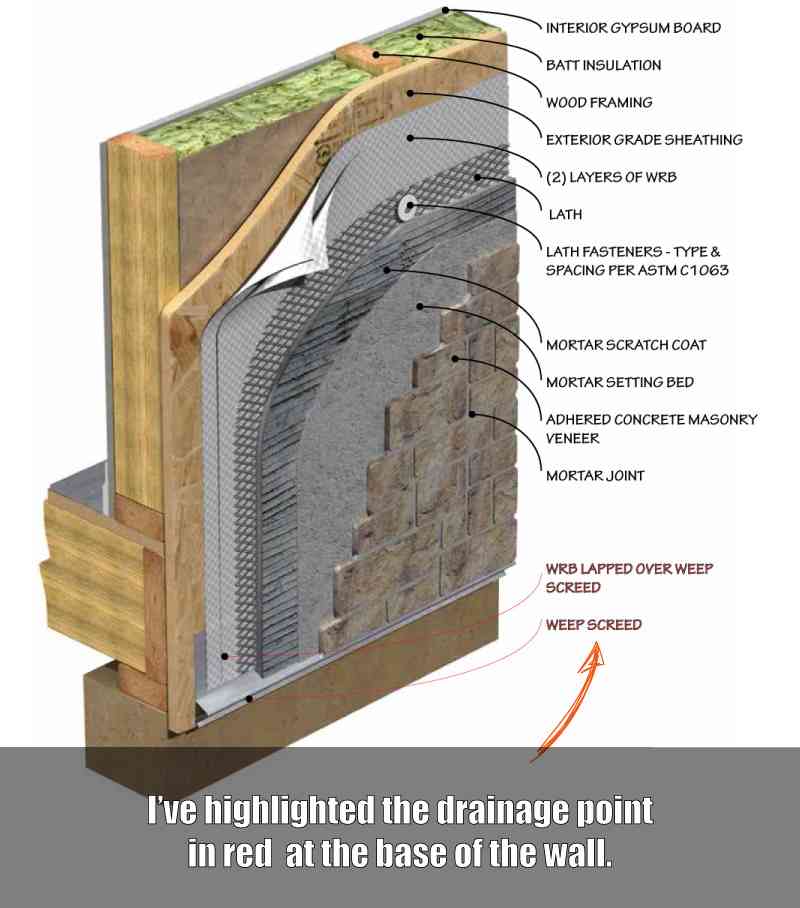

If you want a trouble-free install of manufactured stone, you must create a path for moisture to drain and a place for it to escape at the base of the walls, windows and doors.

If you do not have a drainage point, the moisture will simply build up and rot out the base of the structure. I’ve never seen a home with an escape point, (known as a weep screed) installed, and I look at new construction homes every week. The builders are simply not installing it.

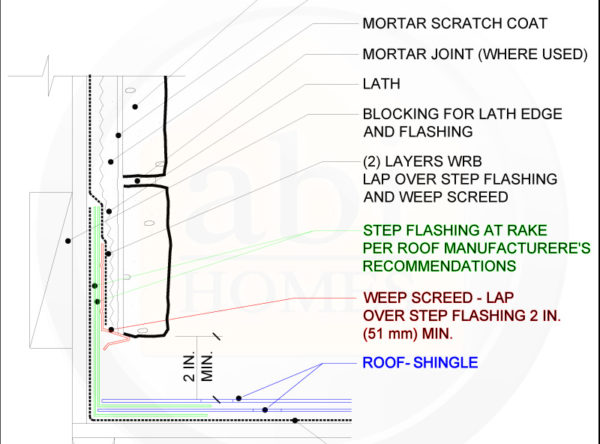

In the wall detail below I’ve highlighted the weep screed in red at the base of the wall. This small piece of flashing will allow any moisture that has built up behind the manufactured stone a place to drain and will allow fresh air an entry point to dry things out.

PROPER INSTALLATION OF MANUFACTURED STONE VENEER SIDING

Hindsight is always 20/20, and now that the problems with manufactured stone are coming to light, we’re getting smarter about it from an engineering standpoint. Unfortunately, the installation on homes is still all messed up.

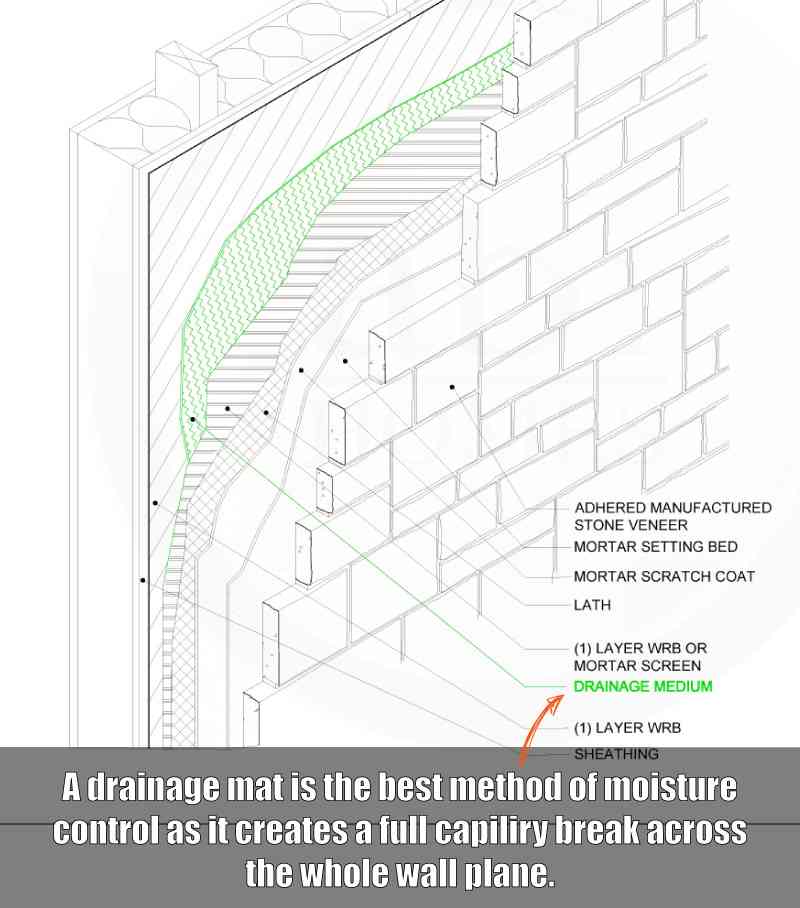

If you actually read the whole MVMA install guide, (You did read it, right?) you’ll see that at the end of the document there are alternative methods for building the manufactured stone veneer wall system.

These include a drainage mat or furring strips mounted to the sheathing of the wall. By adding these details, you will essentially create an air gap between the house and the concrete veneer. Sound familiar? That air gap will allow for moisture control and drainage to occur without the risk of the moisture soaking into the wood structure of the home.

“Is anyone doing this?” you ask.

They’re not doing it here in Louisville, or anywhere else I’ve been to inspect manufactured stone veneer installations.

It’s likely going to take some really big lawsuits to get the ball rolling on correct installs. The process requires more planning, more work, and careful execution to pull off.

Below is a detail for the use of a drainage mat used in place of the furring strips. This method also creates that needed air gap between the manufactured stone layer and the structure of the home.

INSPECTING YOUR HOME FOR MANUFACTURED STONE PROBLEMS

If you have this material on your home and have questions feel free to contact me.

More than likely, your home’s manufactured stone veneer was poorly installed.

I hate to say it, but I’ve never inspected a house that had a proper install. There are ways to take minimally invasive moisture readings from the inside and outside of the home to get a better idea of what type of damage may be occurring in your home.

If you’d like more information on this process, just give me a call and we can talk. I have traveled extensively to help clients with manufactured stone issues, so don’t think that just because you are not in the Louisville, KY area I can’t help.

When big problems pop up with a house, we can usually trace their origins back to a bunch of small details that add up to the current train wreck.

That seems to be the reoccurring theme with the manufactured stone installations that I am seeing now. When the home is missing all of the critical flashing details like weep screeds, kick-out flashing, and casement beads, how can one assume the assembly will perform OK?

Anyone who’s ever spent time on a job site knows the attitude of most construction workers today. Over the many years I’ve worked in the trades, one of the more popular things to hear was, “Looks good from my house,” or “We ain’t building a piano.”

That’s a creative way of saying they just don’t care. They do not care if you have problems later on. If it’s ‘good enough’ to get things cleared, and if it’s ‘good enough’ to get them paid, let it roll.

Ben in Forbes!

I had the honor of being interviewed for an article in Forbes.com about my work with manufactured stone veneer inspections. You can read that here.

MORE STONE VENEER ARTICLES THAT MAY HELP YOU.

I have written many more articles on the subject of manufactured stone veneer. There are two more parts to this series and many case study homes of real-world failure.

If you have a question about stone veneer you can ask that below and I’ll get back to you asap.

I highly recommend you write more content like this! I

simply can’t get enough!

I highly recommend you write more content like this! I

simply can’t get enough!

After reading this I think I’m screwed. Can you come up to Michigan and look at my house? I’m afraid I have rotten walls too.

Hi Ken, Feel free to fill out the contact form here: https://abihomeservices.com/manufactured-stone-moisture-intrusion-inspections/ and we’ll make plans for you.

Ben thank you for the great information. I’ve got a situation that I’m trying to resolve for a customer. I’m not 100% sure that they have manufactured stone. I suspect that they do though and they’re having water that is coming into one of the apartments. I’d love to discuss with you.

Hey! Feel free to reach out via my contact form and I’ll do what I can for you.

Hi Ken, Feel free to fill out the contact form here: https://abihomeservices.com/manufactured-stone-moisture-intrusion-inspections/ and we’ll make plans for you.

Ben thank you for the great information. I’ve got a situation that I’m trying to resolve for a customer. I’m not 100% sure that they have manufactured stone. I suspect that they do though and they’re having water that is coming into one of the apartments. I’d love to discuss with you.

Hi Stephanie – I’ll do what I can for you. Feel free to fill out my contact form and we can discuss things via email.

What about faux rock panels like genstone? Do they cause water problems?

I’ve not seen Genstone used around here Mark, so I can’t give you a certain answer. I will tell you that any product that puts lots of holes in your walls, and lets water get behind it will be a problem over time. I’m a big fan of drainage mats (also known as a rainscreen) like this one: https://www.mtidry.com/products/rainscreen-drainage-planes If a rainscreen is used properly, it should take care of the problem.

Are there any class action lawsuits for this issue/product?

Not that I’ve seen Scott. Not yet anyway. Keep in mind the product performs well if installed correctly (with the proper drainage). The issue that I’m seeing is builders and contractors are not following instructions. As we all know, the devil is in the details.

We just discovered an issue with our stone allowing water to run behind and cause water damage in the wall behind/below the stone. We just started contacting contractors – but the first says they cannot confirm why it is happening without taking off the stone. Should they be able to do this in small areas before removing it all in case the issue is localized? Or if installed wrong it should all be replaced to avoid issue in the future? I also wondered about class action lawsuit… built our house 13 -14 years ago… hard to go back on builder now.

Hi Lori, I’m sorry to hear about your troubles. Most of the time you need to strip things down to the framing and start over. Depending on how bad the water damage is, you may need to strip both sides of the wall- interior and exterior. A good inspector can help you weed through things as most contractors just don’t know enough to be able to tell you why things are failing. As for a class-action suit, I don’t think you’ll ever see it. What you are dealing with is human error, not product error. If I can help in any way just let me know.

I’m a masonry contractor in PA and I’ve just recently started using the rain screen. Before I was just required to use the roofing felt paper and when I saw this product, I’ll never use the felt paper again. The problem I’m having is that everyone want the “stacked” stone look (no joints) and obviously it’s impossible to make a sealed bond with that style of stone. At least with joints you can seal the cracks with mortar. I can just see a driving rain pouring water behind the small, but open joints When I do the stacked look I butter the stone a much as possible before I lay it, mortar gushes out when I lay it, and kinda destroys the point of the stacked look. I do everything I can do to seal the house from moisture, but at some point I’m relying on the builder to have put the house wrap on properly, because there’s only so much I can do.

It sounds like you are doing everything you can to make sure nothing leaks, and that is wonderful. I’ve had to help several homeowners go after their builder for faulty installs. The builder always point to their masonry guy and try to wiggle out of having to pay for it. To protect yourself and the homeowner, I highly suggest you study the MVMA guide and follow it as much as possible. With proper drainage and flashing life is good.

Great article Ben. I’ve been researching safe use of thin stone veneer for past two years and proper WRB and rainscreen products that are available. MTI and Delta Dry appear to be good options. If installed properly is there any risk remaining to wood wall structure from solar driven moisture? Thanks Erick

Hey Erick,

Rain screens are a must for a worry-free install of stone veneer. I have a friend building a new house this summer, and I plan on documenting and showing proper rain screen install. Manufacture stone itself is a fine product, it’s the lazy installs that are getting people in trouble. Thanks for the comment and let me know if I can help in any way.

Great article Ben. What are your thoughts on using the dimpled membrane like what is used in a basement to establish the air gap behind the stone?

Thanks, Kurt. There are several good products available already. They are sold as a drainage mat/medium. Check out Advanced Building Products, they make them in many different sizes.

What about using a product like AirStone around a fireplace? Any issues with that since it would be used indoors? Any health concerns I would need to be aware of with this product? (I have a 3 year old). Thanks, Taryn

Hi Taryn, not that I know of. I actually installed Airstone around my personal fireplace as well (gas insert). The only potential issue I could see with it would be around a traditional wood burning fireplace. They can get really hot and I don’t know what Airstone will do (like off-gas) if its subject to high temps like that. I would reach out to Airstone (or whoever you decide to use) and ask them if its OK to install their product on your type of fireplace.

I was JUST about to get my (real) brick on my 1933 Sears kit home replaced with manufactured stone. Question- what if the new stone is installed up against cinder block? My chimney and base of porch is where the work will be done. Thanks.

The MVMA guide has details for CMU block walls just like they do for wood framing. Be sure the contractor follows those to the letter. Block walls are very porous and you don’t want the water building up inside the chimney. If you are in an area where freezing takes place it could be disastrous. Good luck!

Thank you for this great, informational blog! I was just researching which is the best manufactured stone for my new house and ran across your article! Yikes! Have you seen any problems with NATURAL, REAL stone veneer siding?

Hi Julie, I have seen the same problem on real stone as well when the proper drainage is not installed. When you build your new place, be sure you leave that air gap between the stone and framing, and install the flashing and weeps along the base of the wall to give that moisture a place to drain. If things get placed right against the wood framing you are asking for trouble.

I found this page by chance through a Google search. First WOW! As a first time home owner I didn’t think proper installation of stone siding could turn ugly if you cut corners.

So my question for you is, would the advice you listed here on the page work for stucco homes as well? I live in S. California and while they rain isn’t common out here we had a winter with some brutal rain storms. I would love to install stone siding as like a trim on the house but only if I can find the proper guides for it

I found this page by chance through a Google search. First WOW! As a first time home owner I didn’t think proper installation of stone siding could turn ugly if you cut corners.

So my question for you is, would the advice you listed here on the page work for stucco homes as well? I live in S. California and while they rain isn’t common out here we had a winter with some brutal rain storms. I would love to install stone siding as like a trim on the house but only if I can find the proper guides for it

Hi Michelle,

Stone veneer siding and stucco basically install the same way. In fact, we call stone veneer ‘lumpy stucco.’ If you follow the MVMA guide and use a high-quality drainage matt you’ll be fine. The trick is finding a contractor who knows how to this. Good luck!

I had stone veneer installed over an existing brick fireplace

It is about 10 years old now I havent had any issues with moisture or leaking however I did have it sealed about 3 years ago and now after the harsh winter we had (midwest) the sealant is peeling off with the paint from the veneer. Is there any remedy to stop this?

I had stone veneer installed over an existing brick fireplace

It is about 10 years old now I havent had any issues with moisture or leaking however I did have it sealed about 3 years ago and now after the harsh winter we had (midwest) the sealant is peeling off with the paint from the veneer. Is there any remedy to stop this?

I’m not 100% sure I am understanding your question. When you say fireplace, do you mean the chimney on the outside or your fireplace inside? Email me a few pics and I’ll take a look to see if I can help.

Yes, I’m sorry, the chimney.

Email me a few pictures and I’ll take a look.

Ben,

What link can I email the pictures to? I can’t find an email to attach them to. Thanks!

Ben,

What link can I email the pictures to? I can’t find an email to attach them to. Thanks!

I found your blog via Google search. Thanks for the informative article. My question: I was told that this engineered stone siding could be installed over existing vinyl siding. Is it possible to do that without moisture problems?

No. I would never install stone veneer siding over existing vinyl siding. It sounds like whoever told you that doesn’t truly understand what they are doing.

Hey Ben, Thanks for the great content. I was told the same thing about layering the veneer over existing siding to avoid the issues you mentioned above as long as there is the requisite few inches above the floor and ability to drain in between and enough ventilation. Why is this such a bad idea?

I would avoid doing this as it doesn’t meet any manufactures instructions (that I’ve read) or the MVMA installation guide. It’s been my experience when you try and cut corners by not removing an old wall cladding it just winds up causing more problems.

We have manufactured stone siding halfway up the outside of our home addition. When looking to replace carpeting we uncovered a ton of water filling up our carpet pad like a saturated sponge and rotting the wood in our walls. It has taken us forever to deduct that the water is coming from the stone siding leaking through the house. What steps do we need to take to fix the problem?

Unfortunately, you really have a very large problem on your hands. By the time the water makes it inside, you have saturated wall cavities. Which means it all has to come off, and both sides of the stud wall must be replaced. If you would like to email me some pictures of the problems areas I can try to help as much as possible, but understand there are no shortcuts or easy fixes here.

I have a permastone veneer house built in 1946 and cinder blocks inside. The permastone gets soaked in the rain and I am looking to seal the exterior of the house with a sealant spray – Can you recommend a good product.

You’ll want to go to a professional paint store like Benjamin Moore or Sherwin Williams. They should have some type of product that is breathable you can apply. Just remember that most sealers aren’t going to last more than 2-3 years, so it will be an ongoing thing.

I’d love to get your thoughts on my issue. I have a large chimney with stone veneer in Pittsburgh, PA. Every year i get rather significant amount of stones crumbling down onto my patio. I have not yet put a waterproof coating on the veneer yet, i’m thinking that might be my best option along with, of course, having a good functioning chimney crown. Any suggestions on how to properly fix this type of issue? how to do I send you a photo?

Thanks!

I’d love to get your thoughts on my issue. I have a large chimney with stone veneer in Pittsburgh, PA. Every year i get rather significant amount of stones crumbling down onto my patio. I have not yet put a waterproof coating on the veneer yet, i’m thinking that might be my best option along with, of course, having a good functioning chimney crown. Any suggestions on how to properly fix this type of issue? how to do I send you a photo?

Thanks!

I sent you an email to reply to.

I’m glad you elaborated more on how water will seep into the cracks of stone and concrete and how it will almost always find its way in. Some of the bricks on my chimney are starting to break off and they need to be fixed. This information you shared will be helpful as I look for a reliable masonry contractor.

Hi Ben. I’m building a home with faux masonry along the bottom 3′ of some exterior pillars, which act as roof supports along our wrap-around front porch. The structural pillars are treated 4×4 lumber. But the builder is building a base around the bottom using cinderblock. Then installing faux masonry over that. The top of the bottom pillar will have a stone cap piece. Then, the upper portion of the pillar will be exterior trim wood, installed and shaped to give the columns a more aesthetic look (craftsmen style architecture).

My particular scenario, it looks like the mason has installed weep screeds along the bottom of the masonry edge. So the masonry does not extend all the way down and is not flush with our poured concrete porch. There is about a 1″ gap between the base of the pillar and the concrete porch floor. Cosmetically I am not happy with this approach, since we now have a visible 1″ gap of galvanized metal around the base of every pillar. I would much rather have the masonry from the pillars flush to the concrete.

From reading your article and other forums on this topic, I can understand the need for weep products to allow moisture to escape from wall assemblies that are a part of the home and living space. But these are exterior pillars only. The builder is willing to remove the weep assemblies and install masonry flush to the concrete floor but advises this is against their recommendation. Will I really have much problem in this application since the faux masonry is just on some exterior pillars and not part of the houses wall structures? Thank you for any insight.

Hi Ben. I’m building a home with faux masonry along the bottom 3′ of some exterior pillars, which act as roof supports along our wrap-around front porch. The structural pillars are treated 4×4 lumber. But the builder is building a base around the bottom using cinderblock. Then installing faux masonry over that. The top of the bottom pillar will have a stone cap piece. Then, the upper portion of the pillar will be exterior trim wood, installed and shaped to give the columns a more aesthetic look (craftsmen style architecture).

My particular scenario, it looks like the mason has installed weep screeds along the bottom of the masonry edge. So the masonry does not extend all the way down and is not flush with our poured concrete porch. There is about a 1″ gap between the base of the pillar and the concrete porch floor. Cosmetically I am not happy with this approach, since we now have a visible 1″ gap of galvanized metal around the base of every pillar. I would much rather have the masonry from the pillars flush to the concrete.

From reading your article and other forums on this topic, I can understand the need for weep products to allow moisture to escape from wall assemblies that are a part of the home and living space. But these are exterior pillars only. The builder is willing to remove the weep assemblies and install masonry flush to the concrete floor but advises this is against their recommendation. Will I really have much problem in this application since the faux masonry is just on some exterior pillars and not part of the houses wall structures? Thank you for any insight.

Having the weep screed is needed to help control the moisture with the cladding. It sounds like you have the one builder in all the US who did it correctly. I understand where you are coming from, but removing the drainage path on your columns just because you don’t care of the look of the proper flashing would be foolish.

If our architect/engineer has the same plan as your “installed over wood framing” layers will we be fine? Do we do the stone before the siding?

Is natural stone a better option in regards to moisture issues?

If our architect/engineer has the same plan as your “installed over wood framing” layers will we be fine? Do we do the stone before the siding?

Is natural stone a better option in regards to moisture issues?

I would not install stone veneer on a house without the use of a drainage mat control layer. I’m sure if everything went perfect you may not need it, but I’ve never seen perfect. Giving the moisture a place to drain is key to trouble-free install.

I own a bottom floor condo unit and the building I live in has stone/rock siding on the bottom level. I think that what you have described in this article about water leaking behind and getting trapped and then getting absorbed by the OSB, is what is happening. The HOA has contracted ServPro to look into the water leakage but in my opinion the whole wall needs to be torn down and rebuilt correctly. The building was constructed in early 2013. I would like to go after the builders but was told it’s out of warranty. We don’t currently live in the condo due to mold that developed due to that issue. What do you recommend?

It sounds like you are on track with the cause of the water problems. It may be time to reach out to a construction defect attorney and explore your options. If I can help in any way just let me know.

I just want to thank you – as a manufacturer of stone veneer in Texas, we run into problems all the time with bad installations but our product gets blamed. It doesn’t matter how many times we point them to the MVMA installation instructions but we can’t make them use it. Again – thank you for getting the word out.

You are very welcome. Feel free to share any of my writings if it helps.

My house was done in the 40’s I think with a product that called permastone. My question would be is there any way to get a water tight seal between a new roof and the stone walls. Reluctant to try to saw to cut a channel for the flashing because I don’t know if it will crack and break off because I had a similar problem and this Stone can’t be duplicated

Any suggestions would be appreciated.

My house was done in the 40’s I think with a product that called permastone. My question would be is there any way to get a water tight seal between a new roof and the stone walls. Reluctant to try to saw to cut a channel for the flashing because I don’t know if it will crack and break off because I had a similar problem and this Stone can’t be duplicated

Any suggestions would be appreciated.

If you want to email me a few pics I’ll be happy to look at things for you. If you don’t want to cut a reglet in the siding, you’ll have to roll the dice with sealant. I don’t recommend it, but it can work if done carefully.

Ben:

Am I correct in thinking that brick veneer siding is less likely to present moisture problems than manufactured stone siding? I am thinking of replacing my exterior aluminum siding with brick veneer siding because I like the look of brick, but I want to be confident that the brick siding will last 50 years or more. Do you have any thoughts about the longevity of brick veneer siding?

Ben:

Am I correct in thinking that brick veneer siding is less likely to present moisture problems than manufactured stone siding? I am thinking of replacing my exterior aluminum siding with brick veneer siding because I like the look of brick, but I want to be confident that the brick siding will last 50 years or more. Do you have any thoughts about the longevity of brick veneer siding?

Are we talking about 1/4″ thin brick siding that is what some folks call ‘lick and stick’? If so, it will have the same problems as ASMV if you don’t give the water a place to drain and escape. Masonry products are not waterproof and you must take steps to make sure the moisture never reaches the wood framing.

I have stone veneer in a four season room over exterior grade plywood. The stone never gets wet from rain, but I do llive in Maryland which is a high humidity area. Should I worry about moisture, or even seal the stone?

Hi Adam, Do you mean it’s inside the room- not on the outside of the house?

Yes, on the inside of the room.

I can’t foresee a problem with that type of install. The moisture problems that most people have is due to exterior installs.

Ben,

I’m interested in installing a stone veneer (panel) product to the outside of the block foundation of my home. Any recommendations?

Ben,

I’m interested in installing a stone veneer (panel) product to the outside of the block foundation of my home. Any recommendations?

Hi Brad, Do you have a specific question? Whatever product you use, you’ll want to read, understand, and follow the installation instructions to the letter.

I just had my outdoor fireplace re-stuccoed. They removed the loose stucco and water filled areas, repaired them, put the webbing around the fireplace, applied the gray concrete mix on top and then the new stucco. I left a backsplash area to add ledgestone (12″ high for 170 in. and another 10″ on top of that for 80″ of the in. behind the grill. My contractor is very skeptical about me using this at all saying it will always leak as the ledgestone is not grouted.

Should I find another product for the backsplash, or is there a way to prepare it for the weather?

I just had my outdoor fireplace re-stuccoed. They removed the loose stucco and water filled areas, repaired them, put the webbing around the fireplace, applied the gray concrete mix on top and then the new stucco. I left a backsplash area to add ledgestone (12″ high for 170 in. and another 10″ on top of that for 80″ of the in. behind the grill. My contractor is very skeptical about me using this at all saying it will always leak as the ledgestone is not grouted.

Should I find another product for the backsplash, or is there a way to prepare it for the weather?

Hey Pat,

You must understand that the failures have nothing to do with the products. MSV leaks and fails because human beings don’t install it properly. If a contractor doesn’t think they can install something without it leaking, they may not be the best choice for the job. Make sure whoever is doing the work has read and understands the MVMA guide front to back. There is no better source.

Thank you, I will check that! My other contractor feels it is no problem, so I will review the MVMA guide for additional information.

I am looking at a new home with the veneer stone on the exterior chimney that is a prefab with the stone applied to OSB. The chimney is on an exterior wall and goes through the roof (Stone is exposed on 3 sides). How should this done, I think that I read somewhere that the stone should not touch the roofing shingles?

Hi Bruce – It sounds like you have a typical install that is not correct. All MSV should have a few inches clearance around the roofline to promote drainage. If yours is installed touching the shingles chances are it’s all wrong.

Hey Ben, thanks for the great article and for answering so many questions! We want to install stone over an existing stucco wall. It’s only a couple years old and does appear to have a weep screed at the bottom. Can I just mortar the stone to the stucco and rely on the existing moisture control, or would you recommend installing a second moisture barrier? I’d rather not remove the stucco but will if I have to. Thanks!

That would be a risky thing to do. It may work just fine, but I personally would not do it. We don’t know what kind of fasteners were used with the lathe install, and that extra layer of weight from the stone and mortar may cause a failure in your attachment point. It’s been my experience that every time someone try’s to cut corners on something like this it ends up costing 2x. Once to it the wrong way, and once to tear it all off and start over after the wrong way failed. One more note, I would not install and MSV without a drainage mat. Good luck!

What did you end up doing? I had the same question, but found yours instead.

HI Ben,

Wanted to know if you have ever come across water seepage from the stone into the framing of the house? If so, do you know of anyone who was successful in pursuing their builder or the builders Commercial Liability policy? It appears the builder or builder’s sub did not put weep screed or proper flashing causing infiltration. This could cause repairs to be in the 100’s of thousands. Our house just turned 8 years old. Do you have any advice as to how to pursue them? Thanks Ben! Greg

Hi Greg,

I have helped many homeowners fight the good fight. You may want to read my case study articles I’ve written about the nightmares that can happen from a botched job. You can start here:https://abihomeservices.com/manufactured-stone-moisture-intrusion-inspections/

HI Ben,

Wanted to know if you have ever come across water seepage from the stone into the framing of the house? If so, do you know of anyone who was successful in pursuing their builder or the builders Commercial Liability policy? It appears the builder or builder’s sub did not put weep screed or proper flashing causing infiltration. This could cause repairs to be in the 100’s of thousands. Our house just turned 8 years old. Do you have any advice as to how to pursue them? Thanks Ben! Greg

Hi Greg,

I have helped many homeowners fight the good fight. You may want to read my case study articles I’ve written about the nightmares that can happen from a botched job. You can start here:https://abihomeservices.com/manufactured-stone-moisture-intrusion-inspections/

Ben,

Your blog has me doing more and more research. Thanks to ants, I found evidence of water getting behind our veneer stone on our 9 year old house. I pulled off the baseboard and saw black, so I pulled off sheetrock immediately and realized we had an issue. I thought we knew the two causes, kickout flashing and the flashing about the stone (our stone only goes up to the windows and then an additional 6 inches on each side of the window so they flashed where the vinyl siding meet the veneer stone). With no kickout flashing, water traveled behind the siding and down the wall until it hit a seem in the plywood wall, over time it saturated, and then you know the rest. Where the flashing met the windows on each side was also leaking, as it let water down the J molding and it sat on top of the stone that was under the window and had nowhere to go. Well, now we know a third – we need a drainage mat behind the stone. Luckily, our builder has stepped up and replaced studs, sill plate, rim joist and a very small area of subflooring that needed it. Now it is time to reinstall and I am nervous. The builder has been building for a long time and wants to just put the kickout flashing and “better flashing” where the vinyl meets the stone. I will pay out of pocket for the drainage mat, so I am not concerned about that. What I am concerned about is the flashing and where it meets the windows…how should they make it and install so the water cant get down the J molding again. I can send pics and more details if possible. Any help would be appreciated.

Ben,

Your blog has me doing more and more research. Thanks to ants, I found evidence of water getting behind our veneer stone on our 9 year old house. I pulled off the baseboard and saw black, so I pulled off sheetrock immediately and realized we had an issue. I thought we knew the two causes, kickout flashing and the flashing about the stone (our stone only goes up to the windows and then an additional 6 inches on each side of the window so they flashed where the vinyl siding meet the veneer stone). With no kickout flashing, water traveled behind the siding and down the wall until it hit a seem in the plywood wall, over time it saturated, and then you know the rest. Where the flashing met the windows on each side was also leaking, as it let water down the J molding and it sat on top of the stone that was under the window and had nowhere to go. Well, now we know a third – we need a drainage mat behind the stone. Luckily, our builder has stepped up and replaced studs, sill plate, rim joist and a very small area of subflooring that needed it. Now it is time to reinstall and I am nervous. The builder has been building for a long time and wants to just put the kickout flashing and “better flashing” where the vinyl meets the stone. I will pay out of pocket for the drainage mat, so I am not concerned about that. What I am concerned about is the flashing and where it meets the windows…how should they make it and install so the water cant get down the J molding again. I can send pics and more details if possible. Any help would be appreciated.

Hey Josh, I’ll send you a message to the email you provided here.

Hello Ben,, I am currently having issues with eldorado stone cracking on man made Chimney. The thoughts are that water has gotten in behind the durock clading and expanded causing the cracks. The sheathing was wrapped in house wrap before the durock was installed. Any thoughts on the installation of man made stone over durock?

Hey Greg, you likely have all the missing flashings as well. I’ll send you an email to reply to and shoot me over a few pictures, and I’ll take a look.

The Durok substrate brings up a useful fact in my mind. Did the installer know of the problems, and they tried to put a ‘waterproof’ sheathing up (Durock is not waterproof by the way), or di they install the Durock to try and skip the lathe

Hey Greg, you likely have all the missing flashings as well. I’ll send you an email to reply to and shoot me over a few pictures, and I’ll take a look.

The Durok substrate brings up a useful fact in my mind. Did the installer know of the problems, and they tried to put a ‘waterproof’ sheathing up (Durock is not waterproof by the way), or di they install the Durock to try and skip the lathe

durock is an acceptable backing for eldorado stone. they just want two layers of wrb behind it if used on the exterior.

I’m not sure I follow you here. Are you asking me if Durock is acceptable or telling me it is? I’m not aware of any substrate that doesn’t require two layers of a WRB behind MSV, and I can tell you from the stack lawsuits on my desk most of the time that is not enough. Installing manufactured stone veneer without a drainage mat is just silly and dangerous in my opinion. The odds of moisture making it back to the substrate are nearly 100%. Give it a place to go once it does.

Hey Ben, I live in Nashville TN, and my stone veneer is cracking and falling off of my 5-year-old home. My builder is telling me my warranty is long gone and I’m on my own. I see you are in Louisville, and we’re not that away. Would you be willing to travel down here and help us out?

Hi Steve – I’d be happy to. I’ve helped dozens of folks just like yourself with this exact problem. Please fill out my request form found at the bottom of the page here: https://abihomeservices.com/manufactured-stone-moisture-intrusion-inspections/ and we’ll get the ball rolling. Don’t worry; we’ll get the wrong made right.

Hi Steve – I’d be happy to. I’ve helped dozens of folks just like yourself with this exact problem. Please fill out my request form found at the bottom of the page here: https://abihomeservices.com/manufactured-stone-moisture-intrusion-inspections/ and we’ll get the ball rolling. Don’t worry; we’ll get the wrong made right.

Ben, I live in a 20-year-old Lennar house with a partial manufactured stone facade (first-floor porch and second-floor gable). Everything seemed fine until this year, when water damage started showing up on my garage ceiling and down one of the studs. A couple of inspectors went up on the roof to take pictures of the stone facade, which shows that some grout is not just missing but seems to have never been applied (especially between the stone facade and the Hardie plank that abuts it). Do I have to remove the stone facade to fix the leak, or can I have a water barrier installed from the inside? It seems to me that removing drywall to install a water barrier might be less expensive that removing the stone facade. Alternatively, if I were to remove the stone facade and replace it with Hardie plank, would I have to remove the lath and/or other wall layers in order to install Hardie plank over it?

Thank you!

Ben, I live in a 20-year-old Lennar house with a partial manufactured stone facade (first-floor porch and second-floor gable). Everything seemed fine until this year, when water damage started showing up on my garage ceiling and down one of the studs. A couple of inspectors went up on the roof to take pictures of the stone facade, which shows that some grout is not just missing but seems to have never been applied (especially between the stone facade and the Hardie plank that abuts it). Do I have to remove the stone facade to fix the leak, or can I have a water barrier installed from the inside? It seems to me that removing drywall to install a water barrier might be less expensive that removing the stone facade. Alternatively, if I were to remove the stone facade and replace it with Hardie plank, would I have to remove the lath and/or other wall layers in order to install Hardie plank over it?

Thank you!

Hi Anne, Unforetany, you’ll need to remove the stone veneer (more than likely). I can’t see what is happening with your home, but history has taught me that by the time the water damage shows up on the interior surface, the water damage inside the wall cavity is usually pretty bad. I would start by cutting the wet drywall out from the inside and evaluating what you can see from there. Feel free to reach out to me during the process if you need any help. Good luck with things!

Ben, I am thinking of making an offer on a home that has stucco at the entrance, and the dormers. The house is 12 years old and there is no sign of water damage. However, the stucco looks thin, and there is a couple spots where the wire is visible. I had considered covering these few spaces with manufactured stone, until I happened to stumble on to your

site. I read your reply to the post that was questioning the stucco switch to manufactured stone for the entire home. Is your stance the same for limited areas? I love the house but I will need to either repair stucco or find an alternative because it looks so bad. Being a female on my own, it would be real easy for me to be ripped off. I know nothing concerning construction. The rest of the home is brick. It’s a large 4000 sq ft home. Do you have any recommendations?

Ben, I am thinking of making an offer on a home that has stucco at the entrance, and the dormers. The house is 12 years old and there is no sign of water damage. However, the stucco looks thin, and there is a couple spots where the wire is visible. I had considered covering these few spaces with manufactured stone, until I happened to stumble on to your

site. I read your reply to the post that was questioning the stucco switch to manufactured stone for the entire home. Is your stance the same for limited areas? I love the house but I will need to either repair stucco or find an alternative because it looks so bad. Being a female on my own, it would be real easy for me to be ripped off. I know nothing concerning construction. The rest of the home is brick. It’s a large 4000 sq ft home. Do you have any recommendations?

Hi Sherri – Are we sure the home has real stucco, not EIFS? Most modern built homes I see in my area built in the past 30yrs are almost always synthetic stucco (a.k.a. EIFS). If you want to email me the listing I’ll try and help you sort it out.

Hi Ben,

I have a 1960’s colonial in IL. Our entire first floor is brick, but it is a very dated color. I stumbled across your site because I was thinking about updating the brick on the front of the home by installing stone veneer on top of it. Can stone veneer be installed over existing brick? If so, can it lead to water issues if installed incorrectly, or is the brick behind it preventing that? If yes, I may look into staining the brick instead.

Thank you!

Hi Ben,

I have a 1960’s colonial in IL. Our entire first floor is brick, but it is a very dated color. I stumbled across your site because I was thinking about updating the brick on the front of the home by installing stone veneer on top of it. Can stone veneer be installed over existing brick? If so, can it lead to water issues if installed incorrectly, or is the brick behind it preventing that? If yes, I may look into staining the brick instead.

Thank you!

I would advise against installing stone veneer on top of the brick for a variety of reasons. It may work just fine under certain circumstances, but that would depend on how your brick was installed/flashed/detailed- none of which we know. It may not give you any problems, but then again it may be catastrophically bad later down the road. All masonry products soak up water. If you don’t give the moisture a place to dry/drain, you will have trouble. The stone on top of the bricks may stop that drying from taking place. Good luck with things!

I bought a house in June. I was told about a few cracks in the mortar around the fake rock, but the realtors handyman said he could fix it for 1600.00 but didn’t want to do it. I now know why there are a lot more bad cracks. I have no idea how much it will cost. I’m 80 yrs. old and on a fixed income . This makes me sick. What would be a cheap way to go.

Hi Carolyn, I’m sorry to hear about your troubles. Did you have your home inspected before you bought it? Was any of this brought to your attention before you closed on the home?

Hi Ben…. how often do you see significant structural damage inside the house due to the stone veneer leak? My stone-veneer-front house was built in 2001 — and only in the last 6 months have I noticed nail pops, cracks over doorways, creaking floors, wall blocking protruding from walls, ceiling joists becoming more visible, vinyl siding warping, etc… Homeowners Insurance’s response was: “moisture in the soil can make a house foundation move slightly, blah blah..” and therefore it’s not covered. Can I please get your best guess on whether you think it’s POSSIBLE that stone veneer leakage could’ve caused (or at least was the large caboose in this train wreck of a situation I have). And if yes, would you bump the “possible” up to “probable”….?

Hi Terri, I would need to see the house to say anything. Can you email me some pictures?

This is a very informative article, thanks for sharing about these manufactured stone veneer moisture problems.

Hi Ben,

Thanks for the informative article. I live in central Florida and am considering using Faux Stone siding on my home. Mostly because I’m a DIY and it appears much simpler to install. My question is how well will a Polymere stone hold up in the Florida Sun and heat? Iv read a lot of articles but have yet to find one on color fade.

Thanks in advance for any advice given.

Jay

Hi Ben,

Thanks for the informative article. I live in central Florida and am considering using Faux Stone siding on my home. Mostly because I’m a DIY and it appears much simpler to install. My question is how well will a Polymere stone hold up in the Florida Sun and heat? Iv read a lot of articles but have yet to find one on color fade.

Thanks in advance for any advice given.

Jay

I’m not sure, to be honest. As you well know everything fades when out in the sun, and I’d imagine stone veneer would be no different. If it were me, I’d take a piece and tape half of it off with painters tape and toss it outside for a month or two and see how it holds up. You never know how well it will react. Peel the taped half off and see what difference you have.

Hi Ben,

We just had our new home built and we were initially planning to have a sealant applied to the stone veneer accents to be preventative. We found your article and had a couple questions. The builder did install a weep screed and what looks like a WRB. We have some pictures from the build, but we don’t know if all of the layers you showed were there before the stone went up. We have about 3 ft of vertical stone work across the front of the house, all with a weep screed and the cinder blocks are covered around the foundation, though no screed in that area. Do you think that we should have it sealed? Thanks for any thoughts you have.

Hi Ben,

We just had our new home built and we were initially planning to have a sealant applied to the stone veneer accents to be preventative. We found your article and had a couple questions. The builder did install a weep screed and what looks like a WRB. We have some pictures from the build, but we don’t know if all of the layers you showed were there before the stone went up. We have about 3 ft of vertical stone work across the front of the house, all with a weep screed and the cinder blocks are covered around the foundation, though no screed in that area. Do you think that we should have it sealed? Thanks for any thoughts you have.

Hi Chris, sealers can be used, but they will not correct a botched installed. If the wall assembly was installed correctly, a sealer should not be needed to keep out excess moisture. I doubt it will cause any problems to apply a breathable sealer, but really shouldn’t be needed.

Hi, Ben! We have a new home build with multiple issues with the Eldorado Stone. I would love your opinion on items and would love to send you pictures. We noticed corner cracks on our pillars, etc, etc. I am at the point where I am having the entire front porch redone. Whole house needs redone but I can not afford it at this point. I have been unable to find anyone local to inspect the veneer. (Maryland)

Hi Trish – I sent you an email. :)

Hi Ben,

This was very informative. I’m dealing with some issues that I would like to discuss with a house on the water in NJ.

Hi Ben,

This was very informative. I’m dealing with some issues that I would like to discuss with a house on the water in NJ.

I’m sorry to hear about your troubles. Feel free to email me and I will help you all I can.

Thanks Ben, did you have an email listed? All i was able to find it a contact form

Hi. We live in Indiana and just moved into our brand new home in November. Last week I walked out to go to work and noticed the stone around the front porch fell off! After only 3 months!! Can I post a photo?

Hi Becky, I’m sorry to hear about your trouble with your MSV already. I’ll shoot you an email so you can send me some pics.

Manufactured veneer is cheaper than natural stone, and there is a disadvantages for stone veneer compared to natural stone it is not reusable as natural stones are. Furthermore, manufactured stone veneer has a larger waste factor than natural stone. Being a porous product manufactured stone is subjected to ice wedging and freeze thaw problems. As water seeps into the manufactured stone and then freezes, chunks of the face will pop off leaving a rugged edge which looks similar to the edge of a broken sidewalk. Repair can be expensive as the entire piece of stone must be cut out and replaced. The repair also doesn’t stop the issue from re-occurring.

Very good details and information on this article, helped me learn some of the terms that I wasn’t aware of beforehand. Thanks!

Water tends to be the biggest factor in natural stone sidings or construction…can cause alot of damage if not handled properly.

Thank you for taking the time to share your knowledge, it really is invaluable. You provide a great service.

Thanks, Michelle. Let me know if I can help in any way.

Hi Ben,

I’m planning to install a stone veneer (Ellis+Fisher) on a concrete foundation. Above the foundation I have a vinyl siding. Do I need to install some flashing (metal or vinyl J-channel) between siding and stone veneer?

Thank you

Hi Ben,

I’m planning to install a stone veneer (Ellis+Fisher) on a concrete foundation. Above the foundation I have a vinyl siding. Do I need to install some flashing (metal or vinyl J-channel) between siding and stone veneer?

Thank you

Yes. You’ll want to be sure and install the proper flashing between the two materials so water can not infiltrate that joint. Be sure your flashing is incorporated into your WRB behind the siding.

Hi Ben,

I had some “cost-effective” builders install natural stacked-stone veneer around the concrete base of my house around 2 years ago. They just used chicken wire and concrete to attach to the existing concrete on the base. I had them put flashing between the cedar shingles and the Veneer to stop water coming in from the top, but at the bottom I had them go all the way down to the ground. I have seen no problems yet, but after doing some reading I think I should head off future problems by taking corrective action now. Is it possible to dig down around the house about an inch below the Veneer and put in 2″ gravel to create a kind of “mini French drain” to stop the wet soil wicking up from the bottom? If this wouldn’t work, what would you suggest? The bottom of the Veneer is below the general ground level, so if I just dig it out and put nothing there, it will naturally “fill in”, if you know what I mean. Thanks, Brian

Hey Brian – Is your stone full-thickness or an adhered veneer (thin pieces)? Depending on what they used will depend on what you can/should do next.

Good day, Ben, I really appreciate that you took the time to write this article. I would love to have your opinion concerning a problem that happened to us. My tech sprayed a house for ant control. Unfortunately he had some Palm liquid fertilizer left over in his tank—-So when he treat the home with insecticide, he ended upup staining the walls. I hired a pressure cleaner guy to see what could be done to remove the stains. Bottom line is: he can’t do anything because it’s precast stone. Any ideas??? Thank you, Ben

Hi Judy – since MSV is basically concrete, you may find it all but impossible to get the stains out because of its porosity. I would reach out to the manufacture for the cladding to see if they have any advice on what may work.

I have a question, I am repairing an old fieldstone basement. repointing, the adding a later of umacoat to seal it up. I would then like to add veneer stone panels to make it look better. Should I stud over the finished fiedstone then add the veneer leaving space? Any suggestions are appricted.

Steve

Adding a stud wall in front of your fieldstone basement wall would be best. Leave yourself a bit of room between the layers as a means to decouple the foundation wall from the new stud wall.

If possible, you should leave yourself enough room to slip behind the new stud wall should you ever need to inspect the foundation wall later down the line.

Your website is very informative. Thank You. We are buying a house in North Carolina and just received home inspection report. One finding was as follows: “Clearances were not maintained between stone cladding and the ground and/or paved surfaces to prevent wicking and frost heave problems” I can’t seem to attach picture, but it shows veneer in contact with the ground into mulch. From your experience, how much work is required to repair this so that there is proper clearance? Thanks for your help

That rabbit hole will go very deep, John. Most home inspectors haven’t been trained enough on MSV, and they don’t understand that to get those clearances, you have to remove the lower part of the stone veneer, install the proper weep screed flashing, regrade the soil, and then put it all back together. It’s a big job.

This all assumes that the base of the wall is not rotted already from water damage. If you want to email a few pics I’ll be happy to take a look and offer what help I can.

Thank you for this article.

I live in Phoenix, AZ and was just starting to look at faux stone siding rather than aluminum siding. (Home is built using 1980 simple construction block with a real slump block in front side. Tops of sides a eaves use wood.

I was considering the stone look over the aluminum that would still complement the slump block. The aluminum paint coating I’m told will start chalking before 20 years and potentially leave paint streaks from doing that.

It’s a desert and in a major drought, but we do get some rain plus the very occasional rinse (damn pigeons!)

Any advise on covering the blocks and woods, or should I just leave well enough alone and go with a quality paint job?

Hey Kyler – I’m afraid I’m not following. Email me some pics and I’ll take a look.

Hi Ben,

Great article.

I’m an Architect and recent homeowner of a 20 yr old house that has masonry veneer here in Houston. No rot on sheathing behind when I bought it (opened up the drywall to see).

I’ve sealed over that cast stone with Valspar stone sealant (and colorant for aesthetics) that is supposedly breathable.

I’m in a dilemma now of whether to go over it again with a likely waterproof, non vapor permeable layer that protects against UV fading. This would at once prevent any moisture from getting in at the face, but also theoretically only allow moisture to evaporate towards the sheathing, and not out of the face. What would you do?

Thanks!

I would be hesitant to put anything non vapor permeable on my wall. The risk of trapping moisture would keep me up at night. Most of the failures I see are not at open planes but around windows/missing flashing.

Hey Ben — this is great information and insights. We have a 5-year-old house in the KC metro area with this type of exterior veneer stone and recently experienced some really cold temperatures (wind chills minus 30-40). While we had noticed certain areas of the house getting cold inside, it was particularly bad in our master closet, which happens to have 3 exterior walls with this veneer. The floor, walls and a built-in bench were so cold it was uncomfortable. And then we discovered ice in the carpet area closest to one of the outside walls.

I’ve looked for any obvious signs of moisture leaking, but haven’t found any. The other concern here is whether some type of exterior insulation layer should be required to keep what ends up being a super cold conductor on the outside with no real insulation barrier? What are your thoughts?

Hey Jeff- email me some pics and I’ll try to help you. It is tough to picture without pictures. :)

Our 16 year old house has manufactured stone veneer. After a couple years, many of the stones started to break from the outside and flake off. We paid a lot to have the whole thing replaced, but it is doing it again. I don’t know that we have water leaking into the house, but apparently this manufactured stone stuff dissolves in water. In winter, when it rains, the wind blows the rain onto the front of the house, soaking the stone veneer. Then it freezes and breaks and all the pretty colored part of the stone cracks and flakes off. Is this normal? Is there something we can do to prevent this in the future?

Where are you located, Brad? Climate has a lot to do with things.

Any comments about the relatively new manufactured stone product “Evolve Stone” when properly installed?

No, I’ve yet to see it in the field. Time will tell if it has the same problems as the adhered variety.

I completely agree! I recently had a similar experience with manufactured stone siding on my own home. The initial cost was attractive, but the ongoing maintenance and repair issues have been a nightmare. It’s unfortunate that more homeowners aren’t aware of the potential problems before installing this product. Thank you for sharing this important information!