CSST Gas Lines – Installation and Bonding Requirements

WHAT IS CSST GAS LINE?

CSST is a flexible gas line material that has been used in millions of homes across the United States and the world. CSST is short for Corrugated Stainless Steel Tubing. It was invented in the 1980’s in Japan. The reason for the development of CSST was to improve the safety of gas line systems in buildings during earthquakes. The idea was that if a building started to move during an earthquake, it should have a gas line that moves with it. One of the biggest dangers of buildings during earthquakes is gas leaks that occur after the shaking has stopped.

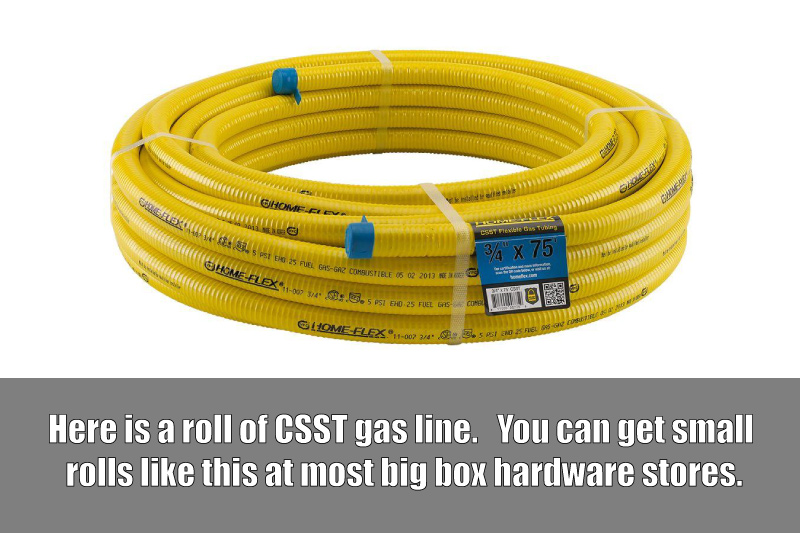

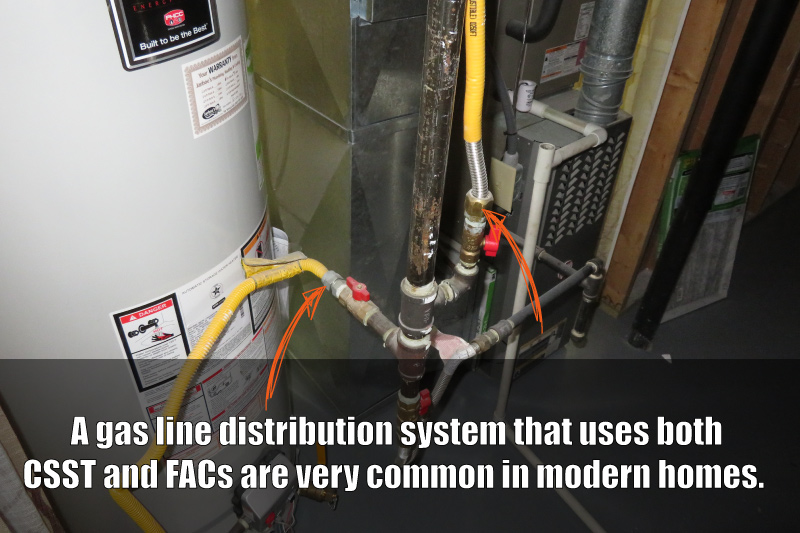

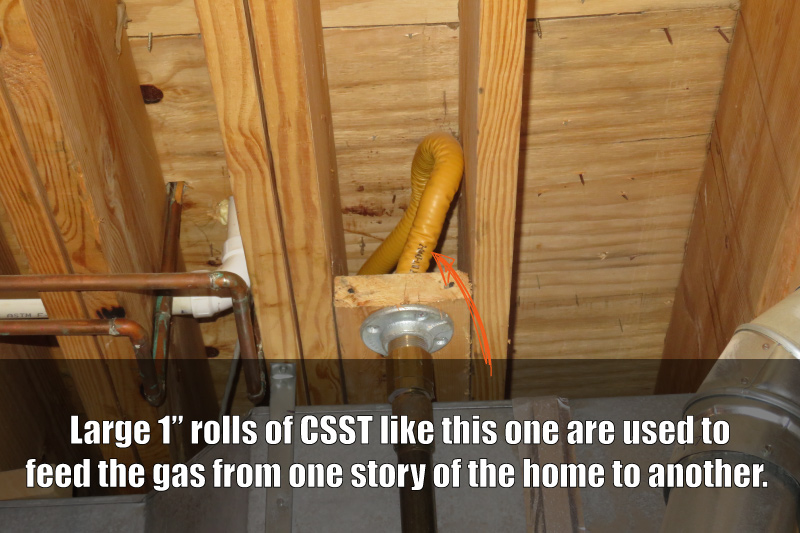

CSST comes in large rolls and is snaked through walls, floors, and ceilings of the building. It is used frequently in construction in lieu of black iron pipe today, which is the traditional material used for gas distribution (both natural gas and propane). If your home is newer (say built in the past 20 years or so) there is a very good chance you have CSST installed as part of your gas distribution system.

What we are learning now is that installations of CSST gas pipe need an additional bonding point to the home’s system grounding for fire safety. There have been house fires blamed on faulty CSST installation without this bonding. CSST is flexible so it can be snaked through the structure. Because it is flexible, the walls of the pipe have to be thin. When certain conditions of an electrical storm are present around/in the home, the CSST can fail, create a gas leak, and start a fire.

Throughout this post, I’ll explain how to verify if you have CSST in your home, what bonding means from a technical standpoint, and how the bonding should be installed. Keep in mind that this job requires you to run wires inside the electrical panel of the home so you’ll want to let the pros handle this one. This is not a DIY repair.

FLEXIBLE APPLIANCE CONNECTOR (FAC) OR CSST GAS LINE

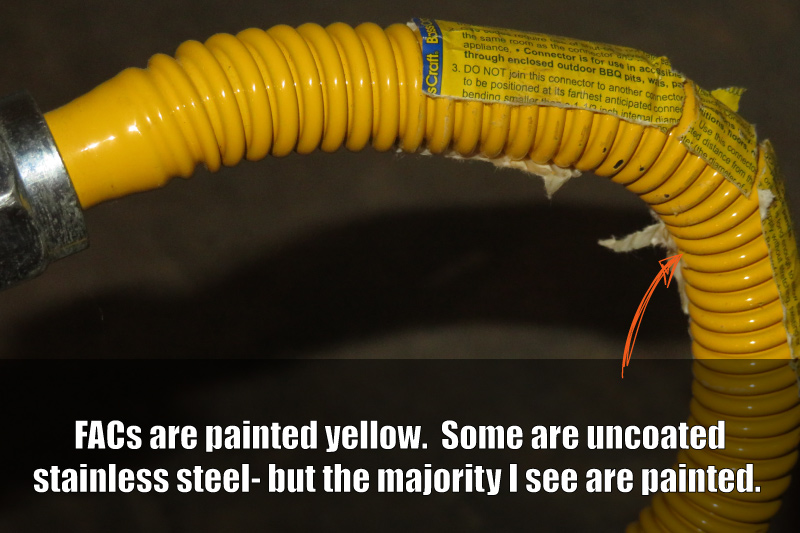

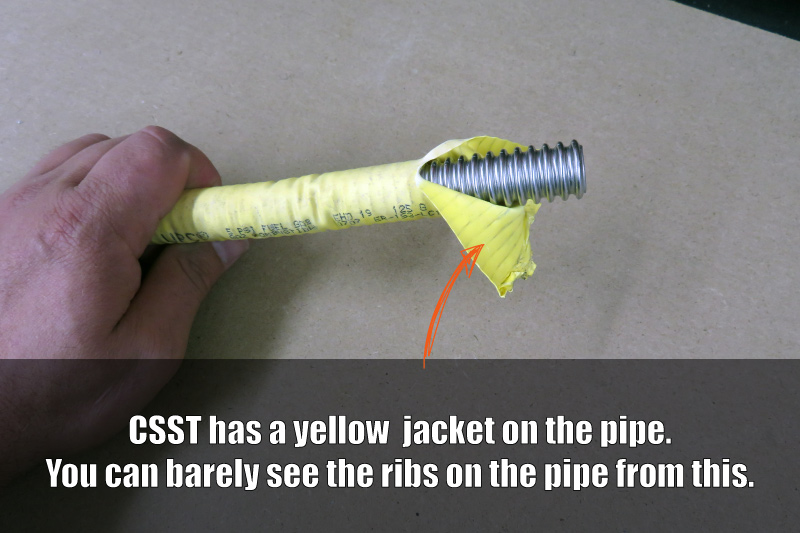

Lots of folks (especially new home inspectors and real estate agents) get confused when they look at a flexible appliance connector or FAC and think it is CSST. To the untrained eye, they do look a lot alike. They are similar in the fact that both are made from flexible stainless steel, and both are typically yellow in color. Yellow is the universal color for anything gas related in a home.

Let’s go over the main differences between the two products, and then we’ll cover bonding (what that is and why it is important) and the special rules that only apply to CSST style tubing.

1. Flexible Appliance Connectors (FACs) are short pre-made store-bought pieces. Usually no more than a few feet long. They are designed to connect an appliance to the gas distribution system of the building, which can be made up from black iron pipe or CSST. CSST comes in rolls as long as a few hundred feet. It is snaked through the building as part of the distribution system and the runs are cut and put together on the job site.

2. Most FACs are painted yellow from the factory. The painted FAC has very pronounced ribs you can see and feel on the tubing. CSST has the same style body, but you can barely make this out because of the thick heat-shrink style jacket that is covering the tubing. The ribs on CSST gas lines are not as pronounced as they are on FACs.

3. FACs are usually smaller in size (diameter) than CSST. Most of the FACs I see are 3/8″ to 5/8″. Most of the CSST runs are 1/2″, 3/4″ and even up to 1″. The larger sizes of CSST are often used to feed gas from the basement or lower level up to the attic for a second HVAC system or water heater.

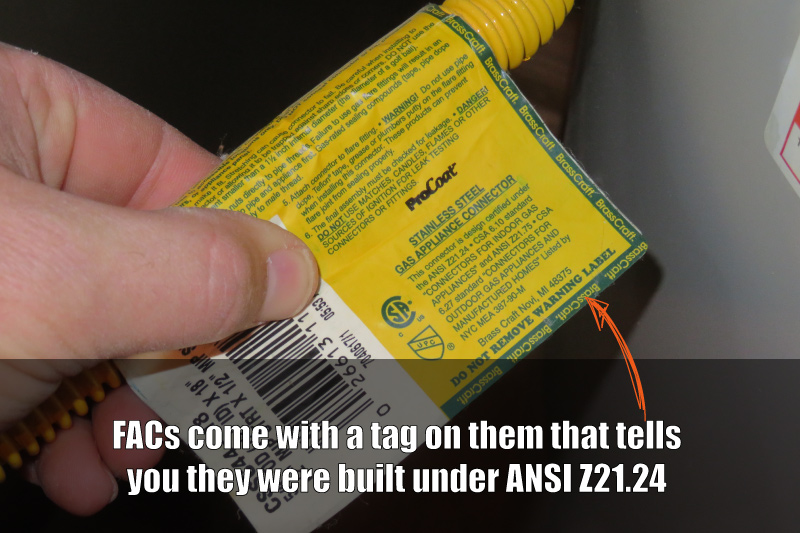

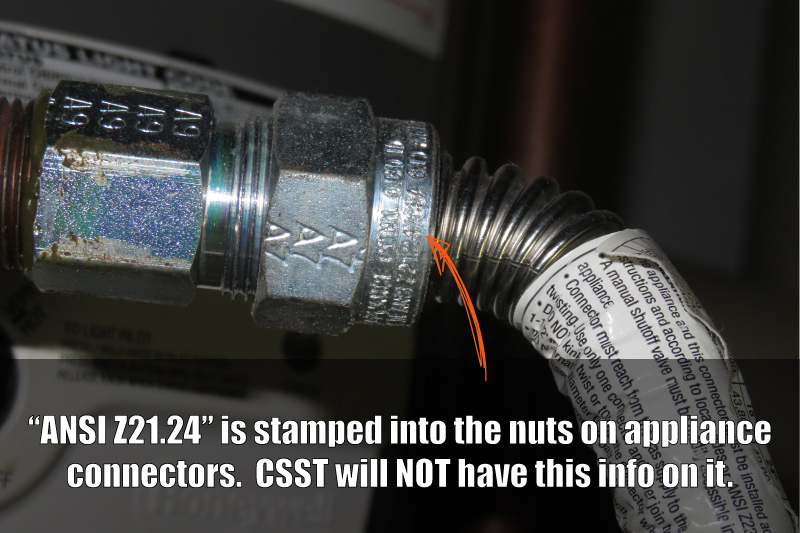

4. FACs will come with a data tag hanging on them, unless the installer tears it off. All FACs are made under the ANSI Z21.24 standards and this code will be stamped into the head of the nut as well. Since CSST is a custom install cut from long rolls and made on site, there is no store bought tag on the line or ANSI rating on the nuts.

Heads Up!

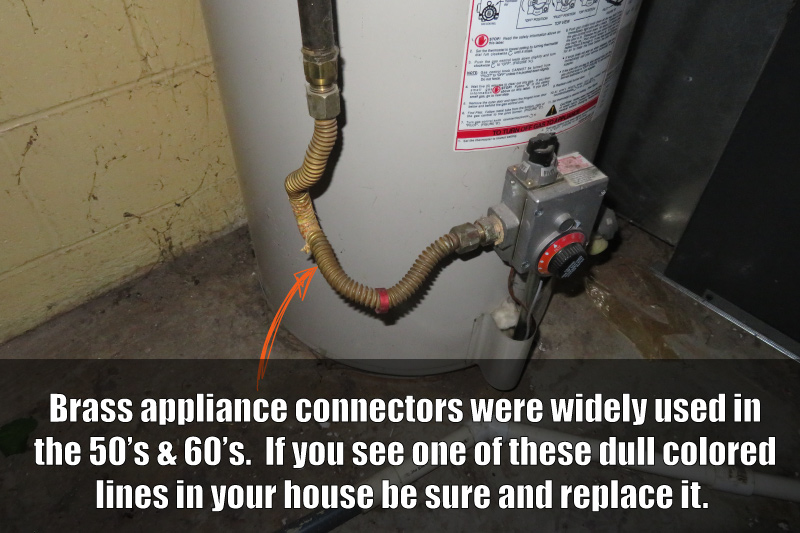

HEADS UP!!! FLEXIBLE APPLIANCE CONNECTORS WERE ONCE MADE FROM UNCOATED BRASS AS YOU SEE IN THE IMAGE BELOW. THEY ARE EASY TO SPOT AS THEY ARE A DULL GOLD COLOR. THESE HAVE BEEN DEEMED A SAFETY HAZARD BY THE CPSC FOR LEAKING AND SHOULD BE REPLACED IMMEDIATELY. YOU CAN LEARN MORE ABOUT THIS BY DOWNLOADING THE NOTICE HERE.

WHAT DOES ELECTRICAL GROUNDING AND BONDING MEAN?

NOW THAT YOU CAN SPOT THE DIFFERENCE BETWEEN CSST AND GAS APPLIANCE CONNECTORS LIKE A PRO, LET’S TALK ABOUT THE ELECTRICAL GROUNDING & BONDING OF THESE GAS SYSTEMS.

WHAT IS GROUNDING?

Geeky Technical Answer: Modern electrical systems have 3 wires in a simple 120v circuit- like your wall switches or receptacles that you plug things into. A black wire, a white wire, and a bare copper. These are the hot wire (black), the neutral wire(white), and the ground wire (bare copper). Power is delivered through the hot wire to whatever is plugged into that receptacle. That device completes the circuit and the current returns back to the source (the electric panel) via the white wire. That’s it. Notice I didn’t use the ground wire at all in this example. It (the ground wire) runs right along the side of the white wire and terminates back at the panel where it is connected to the white wires (neutral wires).

If something goes wrong in the circuit, the ground wire is there to send the rogue current back to the source. Since this path has really low resistance, it causes the amperage to rise in the circuit, and the breaker to trip. Once the breaker trips, that is called “clearing the fault” and you know something is wrong by the loss of power.

SIMPLE ANSWER: When it comes to your home’s electrical system- the “ground” of this system is your plan b in case something goes wrong. During everyday life, the ground wire isn’t doing anything. It is kicked back, watching Netflix, waiting to be called into action. It’s when things go wrong the ground wire steps up and become the hero. If you get a surge in the power coming into your home, or a critter chews up a wire, it will send the power back to the source (the electric panel) so the breaker can trip. This stops the danger of the situation and lets you know something is wrong.

WHAT IS BONDING?

Geeky Technical Answer: Bonding is when multiple metal parts of a building that could carry electrical current (usually wires, or a wire and a metal pipe) are connected together- typically with jumper wires. When this connection is made, each conductor (wires, metal pipes, etc) will rest at the same electrical potential– that is a fancy way of saying everything is even and nothing has a higher or lower electrical charge. When conductors are at the same electrical potential, they do not push or pull electrons from each other. If you were to introduce electrical current on one of the wires, the bonding will spread things out and keep the voltage from wanting to arc (or jump) from one conductor to another.

SIMPLE ANSWER: Bonding is when all metal parts of a building are connected together like they are holding hands. Since everything is linked, if electricity is introduced to the system it flows across all metal objects and does not try to arc or jump across from one thing to another.

TRANSIENT ARCING

When lightning strikes the ground, it releases an extremely high voltage electrical spike that pushes induced electrons in every direction. If this event takes place close enough to your house, it can enter the structure via any available path. This movement of electrons can cause arcing between the building materials that can carry electrical current.

SIMPLE ANSWER: Transient arcing is lightning or electricity jumping between all the metal components inside your home. This normally occurs during a power surge or lightning strike.

WHY DO YOU HAVE TO BOND CSST GAS TUBING?

Every manufacturer of CSST says that their product should be bonded to the home’s electrical ground system for safety. Here is a link to some instructions released by HomeFlex and TracPipe. I’m sure there are many other manufacturers but these are the big two I see in my area. From the research I did, it seems that bonding has been required since around 2006, which means that there are lots of homes throughout the world that have no bonding installed on the CSST. In fact, in my home inspections here in Louisville, KY, I can’t recall ever seeing it done, and I see the product almost daily.

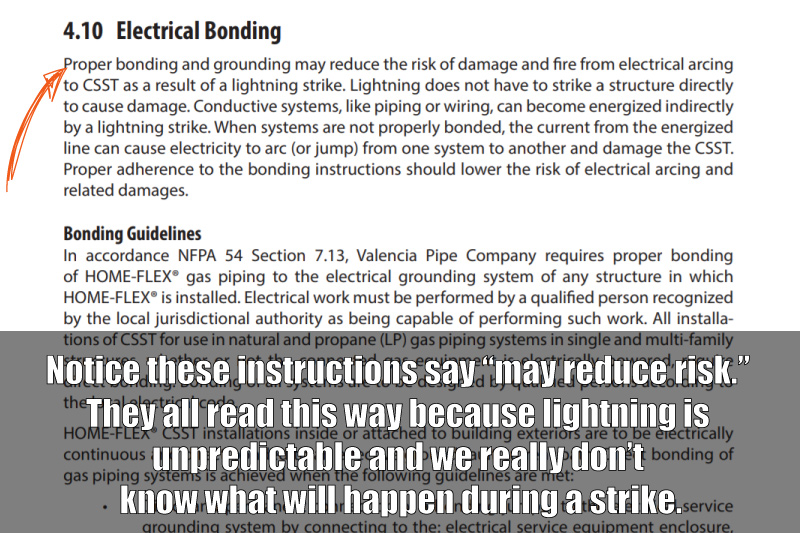

The idea is fairly simple. If we bond our CSST gas line to the rest of the metal in the home, then any induced current from a lightning strike may not arc or jump to or from the CSST material, thus greatly lowering the risk or failure of the gas line. What you really need to pay attention to is the keyword “may.” The truth is you can’t know what will happen, as lightning does what it wants. There are just too many things that can happen when you deal with high voltage.

HOW TO BOND CSST GAS LINES

Bonding CSST is quite simple, you just have to follow a few simple rules. You’ll want to be sure and check with the manufacturer’s installation instructions of the product that was used in your home.

A UL RATED BONDING CLAMP MUST BE USED

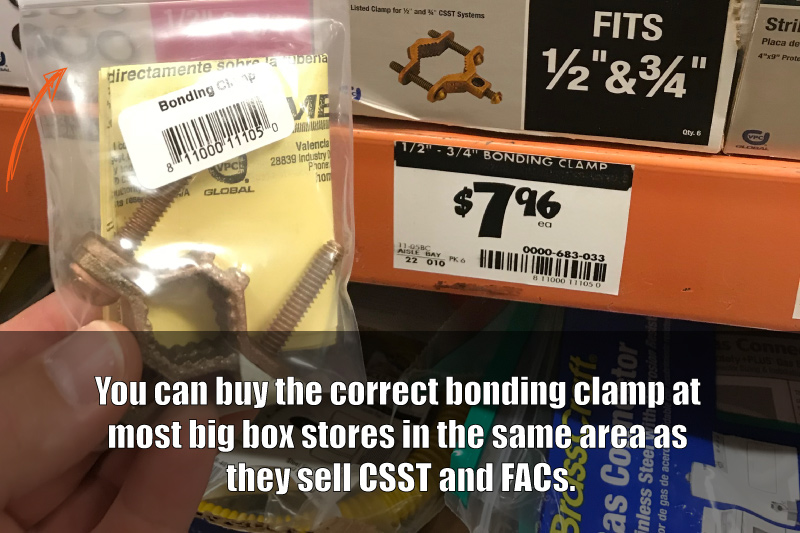

An Underwriters Laboratories listed bonding clamp 467 should be used to make the electrical connection to the CSST gas line. Here is one for sale at Home Depot for a few bucks. Bonding Clamp. These clamps make a solid connection point to the CSST pipe and have a hole and set screw for the wire. And no, you can’t just wrap the wire around the pipe a few times like I’ve had people ask. It’s $8 people…

A CERTAIN WIRE SIZE MUST BE USED

The wire used to create the bond between your CSST gas line and the electrical system must be a heavy gauge 6-AWG copper minimum size. You can go bigger, but not smaller.

THE CONNECTION TO THE GAS LINE MUST BE MADE AT A SPECIFIC SPOT

The connection point made to the gas distribution system should be downstream from the gas meter or propane regulator. Ideally, you want to put the bonding clamp in a spot where the wire will be as short as possible back to the electric panel. You don’t want the current to have to ride 3 miles of wire before it reaches the bonding point at the panel.

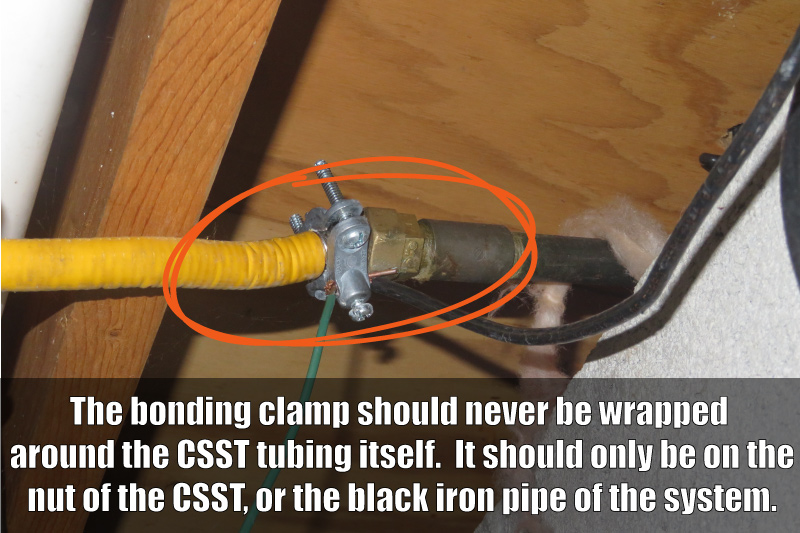

You also need to make sure the clamp is not placed on the actual CSST tubing itself like the photo below. This is a no-no. The clamp should go on the nut of the CSST, or the black iron pipe of the gas system as it enters the home. You run the risk of crushing or damaging the CSST tubing when you place the clamp on it and that is a bad thing.

WHAT ABOUT THE BLACK CSST?

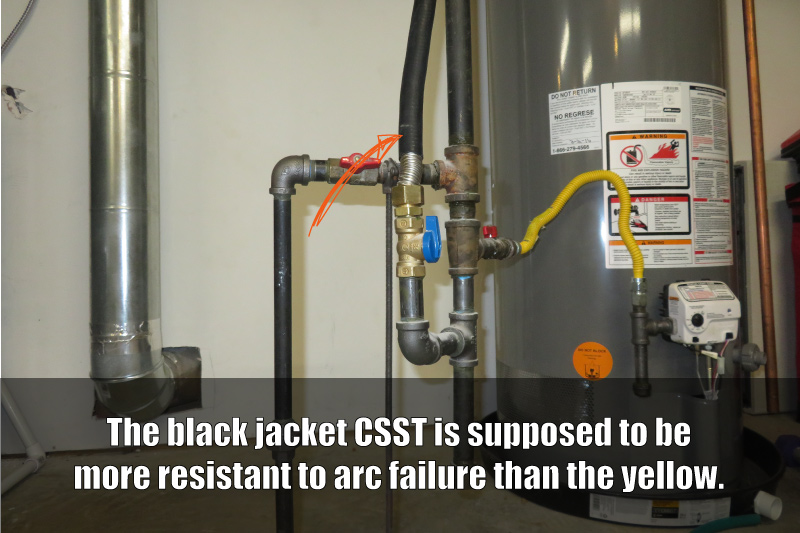

It’s worth noting that there is a newer version of CSST that has a black jacket on it that has been available for the past few years. One popular brand that is sold is known as TracPipe Counter-Strike. An excerpt from their website states:

TracPipe® CounterStrike® is a patented CSST innovation based on our existing TracPipe® CSST product, but that is engineered to significantly decrease the potential for lightning induced damage to fuel gas piping systems. TracPipe® CounterStrike®has been designed with a proprietary jacket material in place of the standard yellow jacket. This black jacket has energy dissipating properties that will help protect the TracPipe® CounterStrike® stainless steel pressure liner as well as other fuel gas system components if the TracPipe® CounterStrike® becomes energized due to lightning.

TracPipe® CounterStrike® is designed to withstand significantly higher levels of lightning energy when compared to conventional TracPipe® with the yellow jacket. TracPipe® CounterStrike® has been shown to be up to 400 times more resistant to the damaging effects of electrical energy than conventional CSST.

No product, including the improved TracPipe® CounterStrike® is immune to the damage caused by a direct lightning strike. Refer to NFPA 780 for lightning protection systems for buildings and building systems.

Does this mean the black stuff doesn’t have the same problems as the yellow? I don’t know. Maybe. I’ve not heard of any failures from the black stuff, but it’s still early. Would it still be a good idea to bond your CSST even if you have the black stuff? Probably. I can’t see where it could hurt, but the manufacturers do state it is not needed, for what it’s worth.

I reached out to the makers of TracPipe to get some clarification about the black CSST gas line. They were very responsive and actually called me back the next day after I emailed them. I talked to a very nice guy named Joe (sorry I did not get his last name.)

Joe and I spoke about the bonding requirements for black CSST. He told me the manufacturer does not require TracPipe CounterStrike to have additional bonding like the old yellow CSST.

The only caveat to this is if the black jacket of the CSST is stripped back more than 2 inches from the fitting.

Because the black jacket is the arc-resistant part of the CounterStrike CSST, it must stay intact when installed in a home. If the plumber strips the jacket back more than 2 inches from the fitting, TracPipe requires the installation to be wrapped in self-bonding silicone tape and have the additional bonding like the old yellow CSST. Joe said this was the ‘unofficial- official’ rule.

The idea is pretty simple. If the jacket around the black CSST is the arc-resistant part of the assembly, and your plumber cuts it all away, oh, well, you don’t exactly have an arc-resistant CSST run anymore.

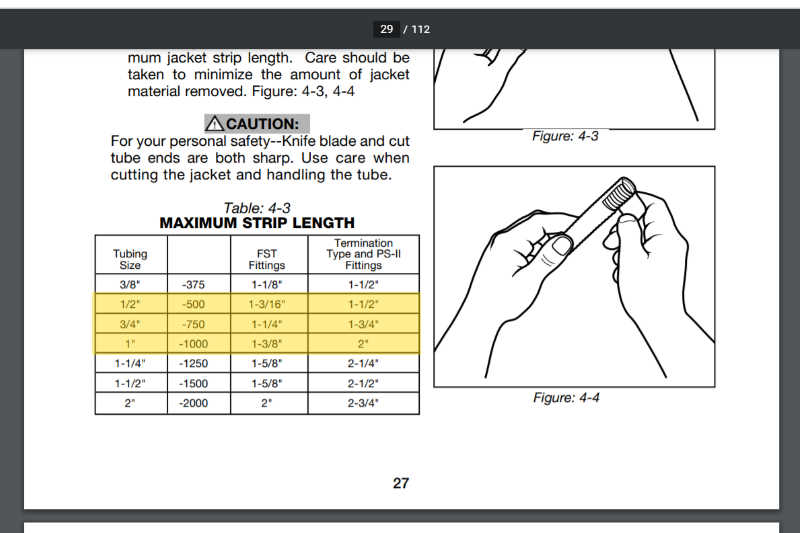

Page 27 of the TracPipe CounterStrike installation guide shows on table 4-3 (see image below) that the maximum allowed exposure of the CSST without the jacket is 1-1/2 – 2 inches.

Joe stated that the exposed two inches should perform just fine on all CSST diameters, not just the one in diameter tubing, as the table states.

If you have black CSST in your home, and the jacket has been removed more than 2 in, I encourage you to reach out to TrackPipe for detailed instructions on correcting this installation.

You will likely have to bond your TracPipe CounterStrike CSST as mentioned above for the yellow version.

WRAP UP OVERVIEW

Important Notice

IT IS VITAL TO UNDERSTAND THAT NONE OF THIS HAS ANYTHING TO DO WITH LIGHTNING PROTECTION FOR YOU OR YOUR HOME.

IF YOUR HOUSE GETS HIT BY A DIRECT LIGHTNING STRIKE, YOU REPLACE WHATEVER IT DESTROYS, AND BURY ANYONE WHO DIES. NO GROUNDING OR BONDING WILL PROTECT YOU FROM 3,000,000 VOLTS.

IF YOU WANT TO LEARN MORE ABOUT LIGHTNING PROTECTION FOR YOUR HOME, YOU’LL WANT TO RESEARCH THE NFPA 780 STANDARDS.

So. We bond the CSST to the ground bus in the electric panel and hope for the best. All of this is worst-case scenario, and most of you will never have any trouble out of your CSST. Just know that if you do have a problem, it can be catastrophic. I encourage you to check your home or have a pro come help check your home to see if you have CSST installed, and double-check to see that the bonding was properly installed. Chances are that it was not done at all, and you need to rectify that.

The ICC (International Code Council) released this document a few years ago that is a great overview of how to properly bond CSST in your home. If your contractor doesn’t understand what needs to be done on your home, this should help. CodeNotes CSST Bonding

I also found this sad story from NBC 5 News in Texas on a house fire that killed a man from suspected CSST failure. House Fire Due to Faulty CSST Installation.

Hey Ben, in the bonding section you refer the bonding clamp and say a UL rated bonding clamp must be used and then you refer to United Laboratories. UL actually stands for the Underwriters Laboratory in Northbrook, IL. They are a service that tests (to failure) every product it certifies.

Good catch Scott. Spell check must have changed it on me. Thanks!

Thank you for sharing. Your article is very comprehensive and thorough. Great job!

Thanks, Aaron.

Thanks for the write up. Just had a water heater installed and noticed the gas line was bonded to the heater water input line. As an amateur radio operator I’m very concerned about bonding. Seems to make good sense. The bond to the water line seems acceptable rather than running a wire to the service box. Agreed?

Hi Rich – There are a lot of moving parts here. If you are concerned with your install I would have an electrician check the bonding of the system to make sure things are done correctly.

Thanks for the write up. Just had a water heater installed and noticed the gas line was bonded to the heater water input line. As an amateur radio operator I’m very concerned about bonding. Seems to make good sense. The bond to the water line seems acceptable rather than running a wire to the service box. Agreed?

Hi Rich – There are a lot of moving parts here. If you are concerned with your install I would have an electrician check the bonding of the system to make sure things are done correctly.

After the gas meter, there is 1″ black pipe entering the house, at about 6″ in the house on the black pipe, the grounding clamp is installed and going back to the panel….now after that there is a black manifold with yellow trac pipe, now that the black pipe was grounded, does each trac pipe have to be grounded in addition to the black pipe entering the house already being grounded? I have an inspector saying they all have to be,thanks

Hi Tom, it is my understanding that a single bond point is all that is required (as long as it follows the manufactures instructions). I would call the maker of your CSST and ask them what they require.

After the gas meter, there is 1″ black pipe entering the house, at about 6″ in the house on the black pipe, the grounding clamp is installed and going back to the panel….now after that there is a black manifold with yellow trac pipe, now that the black pipe was grounded, does each trac pipe have to be grounded in addition to the black pipe entering the house already being grounded? I have an inspector saying they all have to be,thanks

Hi Tom, it is my understanding that a single bond point is all that is required (as long as it follows the manufactures instructions). I would call the maker of your CSST and ask them what they require.

Hi Ben,

I am an HVAC contractor. I have bonded several older CSST gas systems. I am also aware of the FACs on the market today, although it is not a product I typically use. I have never had an inspector flag an FAC on a job before in terms of a grounding requirement. Can you tell me what the code is in terms of grounding the gas piping system, if say it uses black iron up until the point of appliance connection and then transitions to an FAC?

Hi Alex – As far as I know, there is no additional bonding requirement for flexible appliance connectors. Only CSST has this requirement.

Hi Ben, This is the best CSST info site I have found, thanks! I cannot find any information regarding how to properly suspend CSST in my crawlspace. Are special brackets required? And if so, any idea where I might find them? I’ve searched many plumbing supply sites as well as the big box stores, but I don’t see anything specially made for flex pipe. Thanks!

-Nigel

Hi Nigel – I’ve never seen a special bracket installed in a home. I would check the manufacturer and see if they offer anything. If they call for it, more than likely they will sell it.

Thanks!

I’m installing a propane gas stove and will tap off the 220v stove receptical for a 110v for the stove power. Can I use the ground wire on the 220v stove receptical to bond the csst to my main panel?

Thanks

Hey Brian,

I see what you are thinking, and it’s not a terrible idea. However, I don’t think the ground wire of that circuit will meet the minimum requirements of a 6awg wire. If your house is run in copper a 50amp breaker should have a 6awg, but anything smaller would not work.

Keep in mind you want to keep your bonding wire as short as possible, so if you can, make your connection point as close to the panel as feasable.

Can i bond Csst at my furnace to a copper water line ?

Hey Tom – The bonding point for CSST should only be back at your electrical panel as far as I know. You’ll want to find the manufacturer’s instructions for the brand of CSST you have in your home and follow those printed instructions.

If getting to your panel is a hard task, you should call the manufacturer of the CSST and see if they can offer any other solution other than a direct bond to the electric panel.

Thanks Ben for your quick reply.

They say go to the panel.

Thanks

Thank you

Doesn’t all this bonding assume that every joint in the gas line has good metal to metal contact to be able to carry the stray current to the bonding wire? It would seem to me that with all the taped and doped connections in the gas line there is a good possibility that there wouldn’t be a complete electrical path back to the ground. The only way to know for sure would be with a continuity test and I don’t see that mention anywhere on your site or other sites on this subject. Your thoughts.

You could check the resistance across the connections with a meter. I’ve never done it, but I just may the next time I see it for fun. Good idea!

This is a very well informed article, specially since some installation are design on a 2 psi system for residential with multiple appliances and a leak on a 2psi system pressure is not the same as a leak on a 14” W/C system 👍

Ben, when installing CSST (yellow or black) along an exterior wall what is the proper conduit or sleeve material to use? Thanks

Check with the manufacturer to see what they recommend. I don’t know of any requirement for conduit on exterior applications, but it would be a good idea to protect the tubing as much as possible.

In my garage above the ceiling I have a stretch of about 30 ft of Pro Flex with black pipe connections on both ends. Should it be grounded on both ends or just one end? It also has a pro flex union in the middle.

As long as your CSST line is properly installed, a single bonding point is all that is called for.

This blog post is fantastic. I searched far and wide for info on this topic and though I am a lay person and read through a few others, this is THE most informative.

My question however, is this: We had a new stove installed a couple years ago and it has what looks like the yellow CSST attached to the stove and to the gas line on the wall. There is no clamp or anything appearing to bond or ground this tubing. Should we get this stove connection bonded and grounded as well and if so, who would we call.

The appliance dealer doesn’t do this type of work and I have no clue where to turn. Would this type of work go to an electrician, HVAC, plumber, handyman or who??

Thank you for your response!

More than likely, you have an appliance connector, not CSST. I explain the difference at the beginning of this article. If you can see your feed line, double-check if the yellow is paint or a plastic jacket around the pipe. If it’s paint, you have an appliance connector, and bonding is not needed.