Review of Bone Dry Roofing

Most people will only purchase one roof for a home in their lifetime…two if they are unlucky. Because this is such an infrequent purchase, most homeowners don’t know much about the process of installing a proper roof. So, when it came time to have a new roof installed on my home, I decided to document the process and show you what a quality roof install should look like.

The purpose of this article is not to train young and budding roofers, but to give you, the homeowner, a peek into what you should be getting when you hire a roofing contractor for your home. Poorly installed roofs are by far one of the most common things I find during my home inspections, so I know that a lot of you are not getting the quality work you think you paid for.

So, who did the home inspector pick to do the roof on his own house? Bone Dry Roofing

And they did a fantastic job.

Honestly, if you are lucky enough to live in a city that this company services, you can stop reading now and call them for your new roof. For the rest of you who don’t have a Bone Dry Roofing nearby, let me show you why these guys are at the tippy-top of the roofing contractor world–and what you should be looking for when hiring a roofing company.

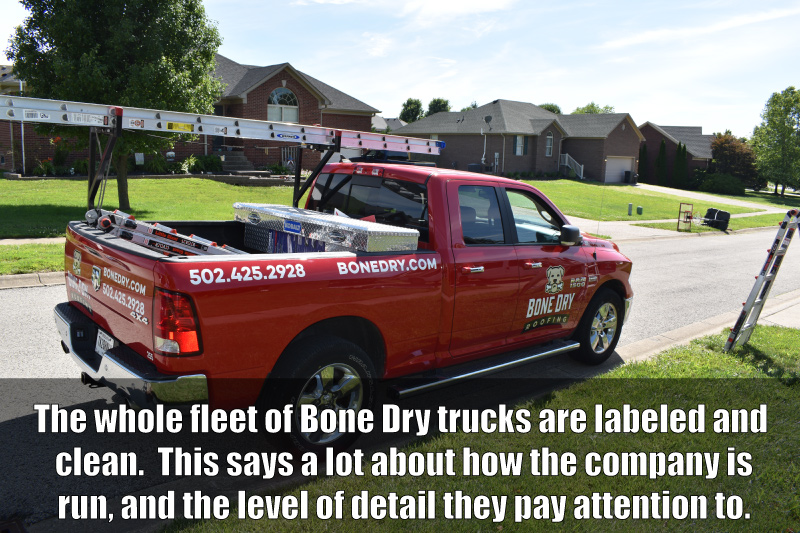

Bone Dry Roofing started just up the road from me in Indianapolis back in 1989. They opened their Louisville KY branch some 20 years later. They now have over 10 offices across six states, but don’t let that growth fool you into thinking they have forgotten their roots. Bone Dry Roofing is still family-owned and operated, just like they were back in Indy all those years ago, and it shows in the quality of care they give their customers.

CUSTOMER SERVICE IS #1

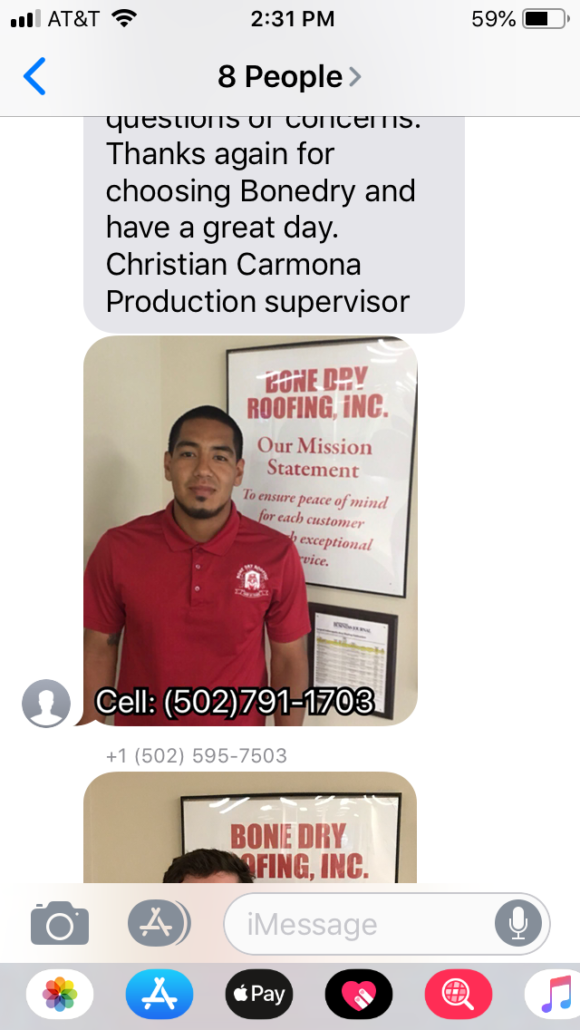

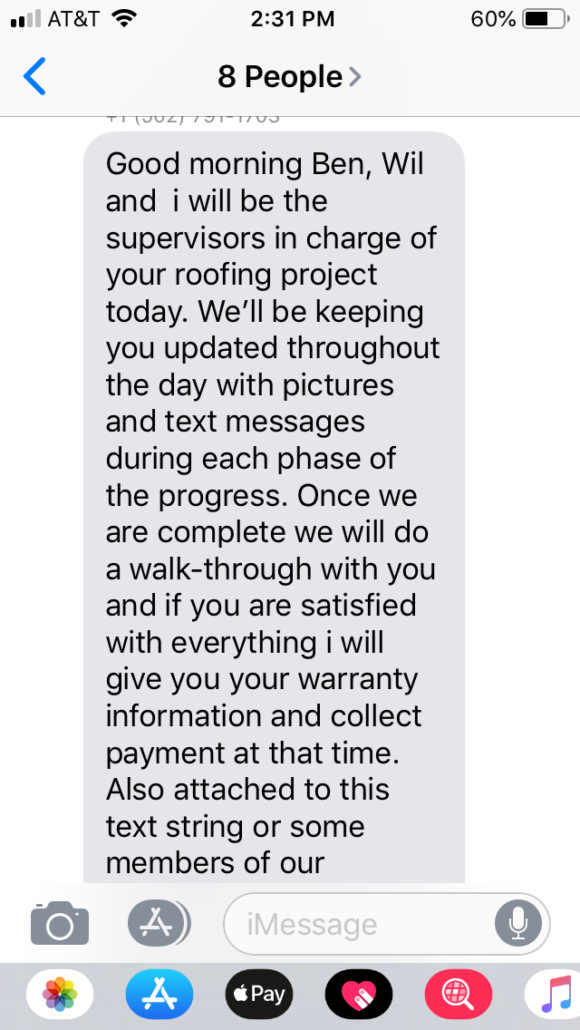

The night before my install day I received a text message from Christian (one of the project managers from Bone Dry assigned to my house) letting me know they would arrive around 6:45 AM. This set the tone for what was truly an impressive experience. The day of the roof install, I received another text around 6 AM–this one with a group of 8 other people that included the owner of Bone Dry Roofing, the field managers, and me, the homeowner. This was the first in a text chain that continued throughout the day, giving updates on each phase of the job to all of those stakeholders. I imagine most customers don’t hang around all day as I did, so this is an invaluable courtesy to someone who likes to keep track of what’s happening but can’t be there in person.

6:44 AM – The first of the crew arrived at 6:44 AM–one minute early. I love this. They were right on time. Tardiness shows a lack of respect for someone else’s time and it’s a pet peeve of mine. Clearly, Bone Dry Roofing and I think alike in that regard. I know some folks will groan about contractors making all that racket so early in the morning, but sometimes you need to beat the heat, and roofing is a HOT job. They want to avoid the midday sun as much as possible. Luckily, my neighbors are all great people and when I told them of the early start, they totally understood.

The guys started by prepping everything around my house that may get damaged by falling debris, including my patio, plants, trees, doors, windows, A/C units, etc. Everything that may get damaged or possibly scratched by falling shingles got covered.

TEAR-OFF THE OLD ROOF

Once everything had been covered up and protected, the first guy mounted the roof and installed the fall protection. These are heavy duty metal rings that are nailed into the structure of the roof framing. Ropes and straps are tied into these rings and then onto the harnesses used by the roofers. If someone were to slip during the job, this rope and harness system would save them from falling to the ground. Clearly, it is very important to get this safety gear perfectly installed. From a liability standpoint of a homeowner, it is fantastic to see. Lots of roofers skip this crucial safety step, as it can slow the guys down during the installation. It’s great to see a company care enough about its crew that they won’t sacrifice safety for speed.

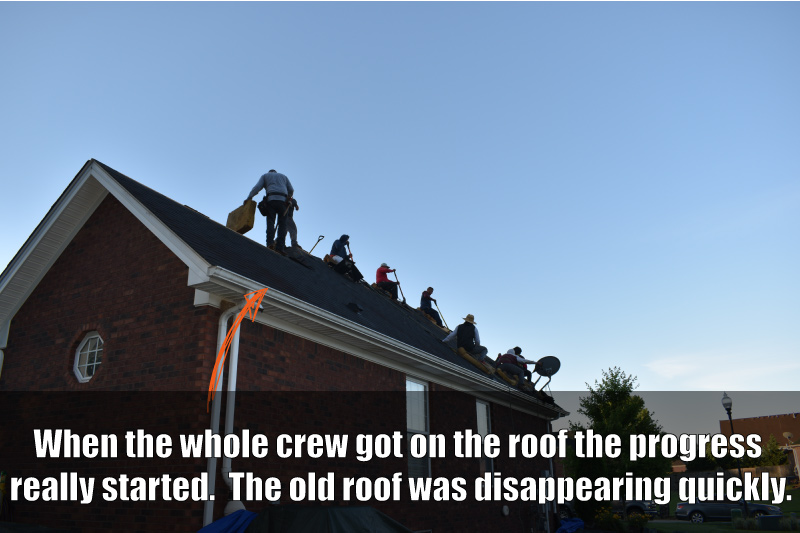

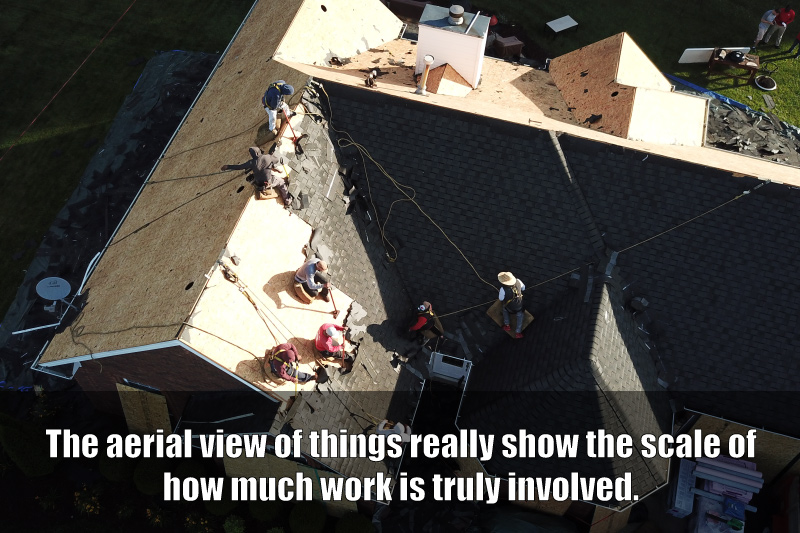

It didn’t take long for it to start raining old shingles around my house. The whole crew was up there peeling back the old roof, and it was borderline dangerous to go outside. I was in and out all day to take pictures and had to watch my step with nails and falling debris. If you plan on staying home for this project or have pets and kids that will want to go outside, be sure you speak to the crew leader to make a game plan. It shouldn’t stay this bad all day, but my tear-off process and cleanup took around 4 hours.

DETAILS MAKE ALL THE DIFFERENCE

The real difference between a quality roof install and what most folks end up getting is in the details that get covered up by the shingles. Don’t think for a second that shady storm chasing roofers aren’t clever enough to make their work look great on the surface while skipping all the critical steps under those shingles to cut costs and save time. I’ve already given you my opinion on adding a second layer of shingles, but now let’s take a look at what should be going on underneath.

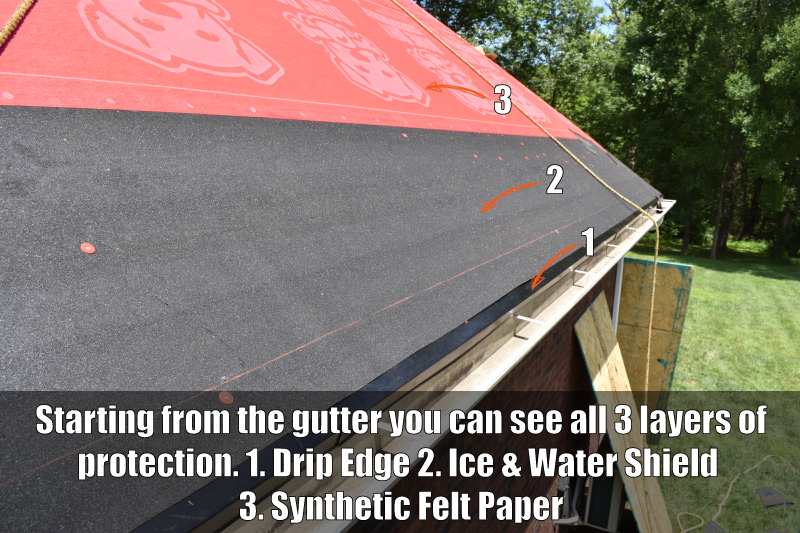

DRIP EDGE FLASHING

I see a TON of homes without drip edge flashing installed on the roof. Drip edge is a thin, angled piece of metal that gets nailed down along the edge of your roof to cover the wood all the way around your roof–360°. It covers and protects the edge of the wood sheathing from water that sometimes wraps back around the bottom of the overhanging shingle. If the drip edge is omitted from the roof, the wood along the edge of the roof will rot away over time.

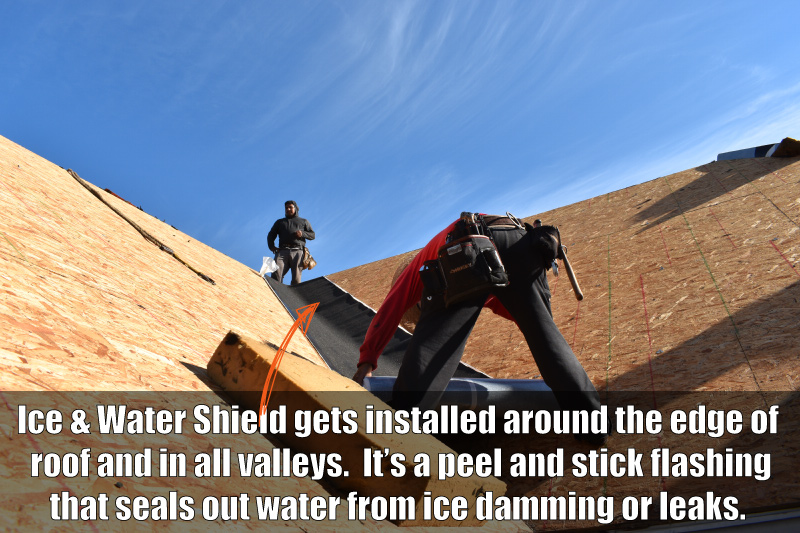

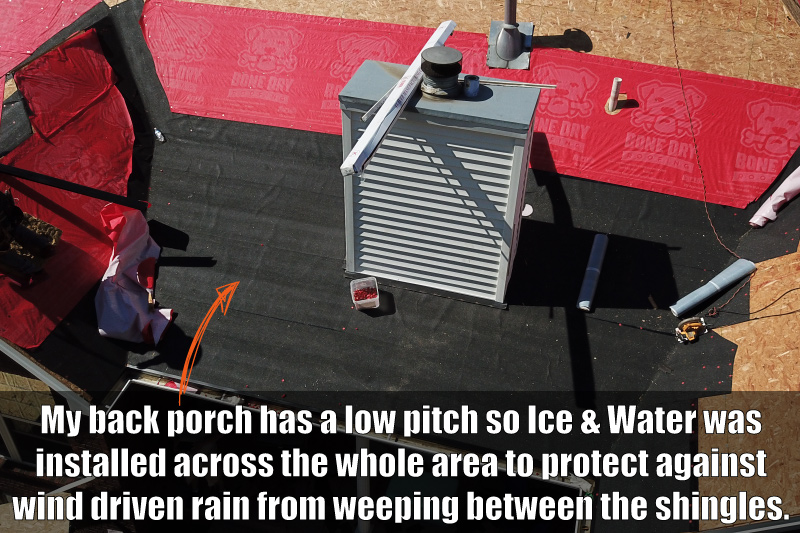

ICE & WATER SHIELD

Ice and water shield is a peel and stick membrane that is applied to all valleys, eaves, and low-sloped areas of the roof. It almost reminds you of a roll of shingles that is super sticky on the back. The roof deck is cleaned off, and this material is applied to all the areas where roofs normally leak: valleys, eaves, low slopes, etc. This step is almost always skipped by ‘budget roofers’. The cost is minimum to install, and given the extra layer of protection it awards, it’s crazy not to use it.

SYNTHETIC FELT PAPER (UNDERLAYMENT)

Underlayment is a protective layer that gets installed before the shingles go down. Its primary job is to keep your roof from leaking in the event that you have shingles blow off or a delay in the installation of a new roof. For decades, there were only two real options: 15lb or 30lb ‘felt paper’ (this was an asphalt-coated paper). In recent years, most quality roofers have switched to a synthetic underlayment. It’s stronger than the old asphalt felt, and lighter/easier to work with. It does come at a higher price than the old stuff so keep in mind that not all roofers will use it. Bone Dry Roofing uses nothing but its own branded synthetic underlayment.

ALL THE LAYERS

Here is a great shot of all three protective layers installed. Everything is installed in a ‘shingle’ like fashion because water runs downhill. Once a quality shingle gets installed on top of this, you are looking at a true 30+ year roof install.

PROPER ATTIC VENTILATION IS IMPORTANT

The last step in the preparation is making sure the ventilation is correct for the roof/attic. When my home was built back in 2000, the roofer used box vents every 10 feet or so across the main roof slope, but that was it. Bone Dry Roofing closed off the old holes from the box vents and installed new ridge vents across the main roofline and all the smaller ridges as well. This should help promote even venting of the attic and help ensure that I don’t have any problems.

TIME TO INSTALL THE NEW SHINGLES

HAND NAILING SHINGLES

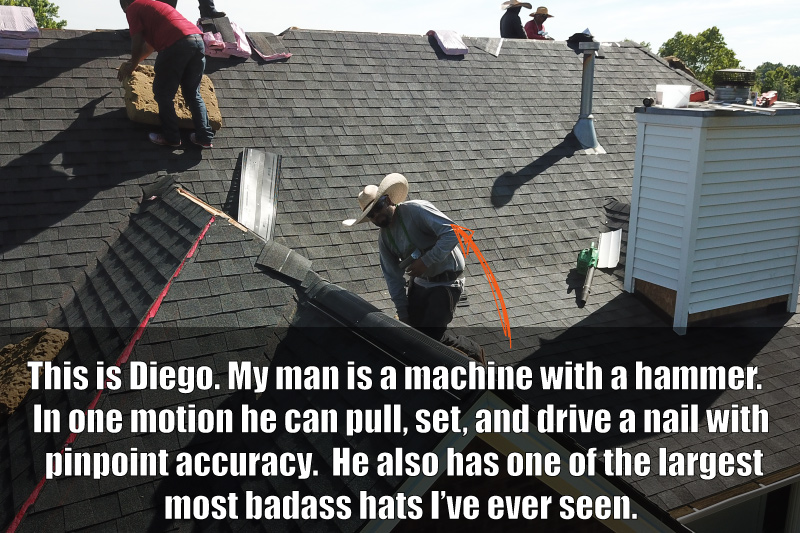

After a well-deserved lunch break of BBQ smoked chicken and burgers cooked by yours truly, it was time to start slinging some shingles. The guys had already put in almost 6 hours of hard work, and I was tired for them, but they didn’t slow down for a minute. Once again the whole crew climbed up on the roof and quickly fell into a groove. It was amazing to see how fast these professionals could nail down the shingles.

The entire roof was hand nailed (in lieu of using nail guns). This shows you how much Bone Dry Roofing cares about their product. Very few roofing contractors hand nail shingles anymore. It’s just too slow compared to gun-nailing the roof. But what you sacrifice in speed you more than make up for in quality. I’m sure lots of folks will argue that you can put a good or bad roof on both ways, and that would probably be a fair argument. However, what you can’t argue is the communication or control you get back from the house when a roof is hand nailed. You see, sometimes when you drive a nail it doesn’t ‘hit anything’. This means you have a loose spot from the lack of structural connection. When that nail is hand driven, you feel the lack of resistance, and you know something is not right. With a nail gun, you don’t. You also have much greater depth control with hand driven nails. Lots of roofs that are installed with nail guns have the fasteners over-driven from running too much air pressure, and the shingles blow off in large sheets later in life during a wind storm.

A hand nailed roof, in my opinion, is a far superior way to install a shingled roof.

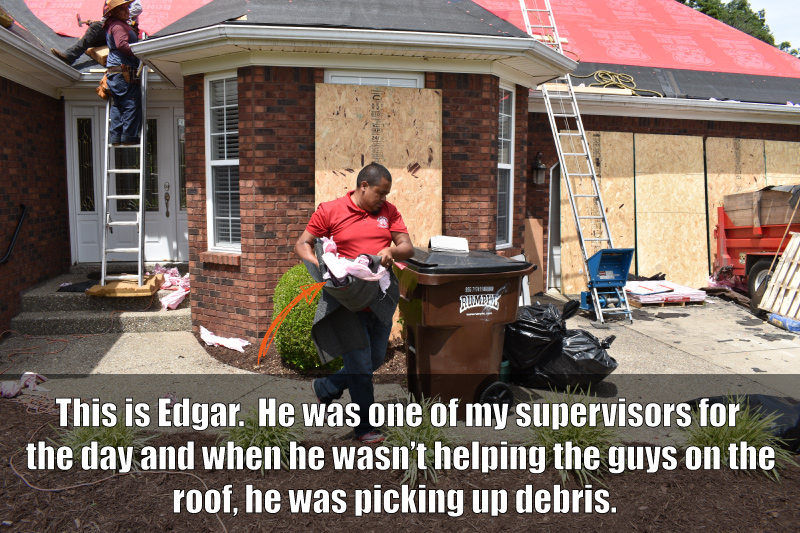

MEET THE TEAM AT BONEDRY ROOFING

THE FINAL TOUCHES

You would think that once the shingles were installed it would almost be a wrap.

Nope.

The guys finished the shingles around 5 pm, and they still had another 2 to 3 hours of details to finalize. No one seemed to be rushed. No one complained about working late. My roof was 40 squares large and they needed that extra time to finish things up.

Once all the shingles were installed on the main parts of the roof, the ridge vent system was installed over the slits that were cut out earlier in the day. This system allows the attic area to constantly vent or “breathe,” but doesn’t allow water to leak in. Once all the plastic vents are installed they are covered with ridge cap shingles to protect everything from UV damage. (It also makes it look nice.)

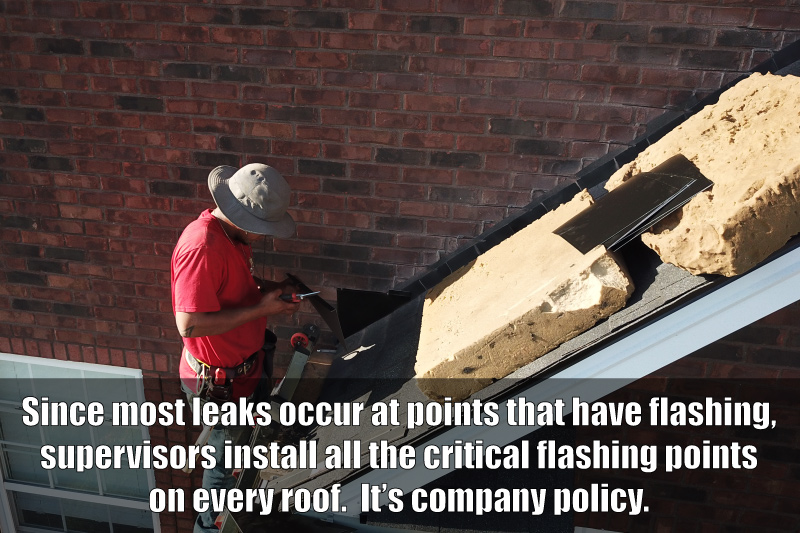

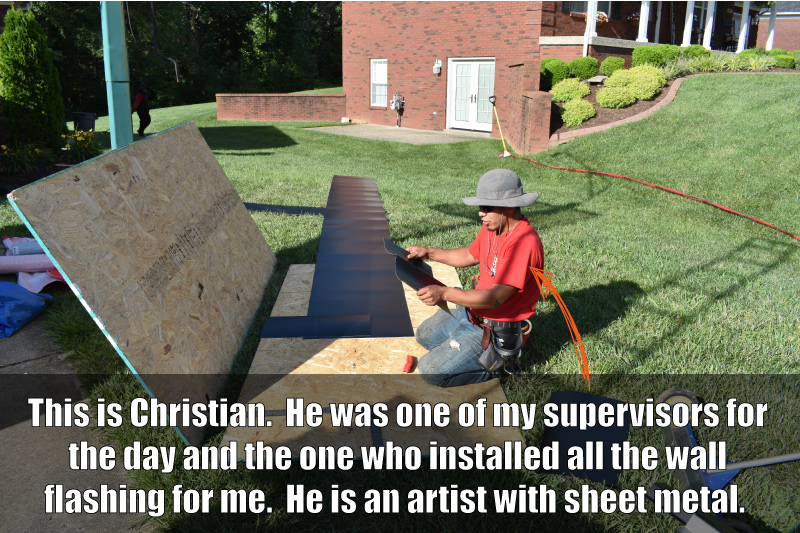

WALL FLASHING IS A TEAM EFFORT

Most roof leaks happen when the roof plane changes direction, around a penetration (like a plumbing vent pipe), in dead valleys, etc. In other words, you usually do not get a leak in a wide-open spot on a roof slope. At Bone Dry Roofing, all flashing points are installed by the on-site supervisors to make sure your roof stays trouble-free. Since my roof is a ‘hip’ style, I don’t have much flashing to worry about. However, I have one small bump-out roof that needed to have step flashing and wall counter flashing installed.

It doesn’t surprise me that Bone Dry Roofing takes the time to do this correctly, but it deserves recognition because I hardly ever see it during my home inspections. Once the reglet has been cut, Christian bends one side of the metal so it can be tucked into the wall. A nail is placed into the groove as a wedge to hold the metal in place, and then things are sealed with a caulking sealant. The extra step of cutting the groove and tucking the metal into the wall creates a mechanical joint that prevents water from getting behind it. Even if the caulk fails, the tucking of the metal will stop the water from seeping in behind it. Well done Christian.

THAT’S A WRAP! 8:35PM

Yup, you read that correctly. The crew started at 6:44 AM and finished at 8:35 PM. The guys took one short lunch break. I’m still not sure they’re not machines.

If you can’t already tell I’m a big fan Bone Dry Roofing and what they do. It takes a lot to impress me and the guys there have blown me away. I may even steal a play or two from their book and implement it into my own business. I can’t thank them enough for all of their hard work and the stellar job they did on my new roof. They are true craftsmen, and I could not ask for a better job. And, in case you are wondering, roofs are not all they do. Bone Dry Roofing offers many more services including siding repair, guttering, chimney repair, masonry repair, and commercial roofs. If it involves the exterior of a building they do it, and I’ll bet they do it better than anyone else.

Below is a small gallery of my new roof. Take note of how straight and perfectly lined up everything is. This only happens when the contractor installing the roof takes their time, and when the whole crew is working as a team. It’s not an easy task to keep those long runs perfectly straight around such a large area.

Bone Dry Roofing has reached the top level with Owens Corning with Platinum Status. This is the manufacturer’s highest destination of preferred contractors. This means that when you get the platinum-plus level roof installed, it’s backed by a 50-year parts and labor warranty by the manufacturer of the shingles, not just the company installing it.

According to the Owen Corning website, Bone Dry Roofing is the only roofing contractor in the Greater Lousiville Area to be awarded every credential they offer.

Ben Hendricks

Hi, I’m Ben, and I inspect houses. I grew up with a hammer in my hand, and have been a professional home inspector for 15 years. My blog is here for info about home inspections around the Louisville, Kentucky area, and just about anything construction-related.