Leaking Adhered Manufactured Stone Destroyed Retail Shopping Center

LEAKING ADHERED MANUFACTURED STONE ON COMMERCIAL BUILDINGS

The purpose of this article is meant to show that the moisture problems with adhered manufactured stone installs are not isolated to residential construction. The installers are screwing up on commercial buildings just as bad–if not worse.

I was called to investigate leaking windows on this strip mall in February of 2017. The property management team was planning on having to caulk a few joints here and there to seal things up. They could have not been more wrong. What I found was a 14-acre complex that is so botched up it would make you sick to your stomach to think about. Just like residential homes with leaking manufactured stone, all of the flashing details on this complex had been omitted, and they were faced with a failed wall system that was rotting from the inside out.

Because this was a retail shopping complex, I wanted to keep the invasive testing to the outside of the building. People were trying to conduct day-to-day business, and they didn’t need me drilling and cutting through the walls while customers were around. I opted to take my samples from the outside, instead of through the walls on the inside. This worked fantastically and I’ll keep this method of testing as an option for homes as well.

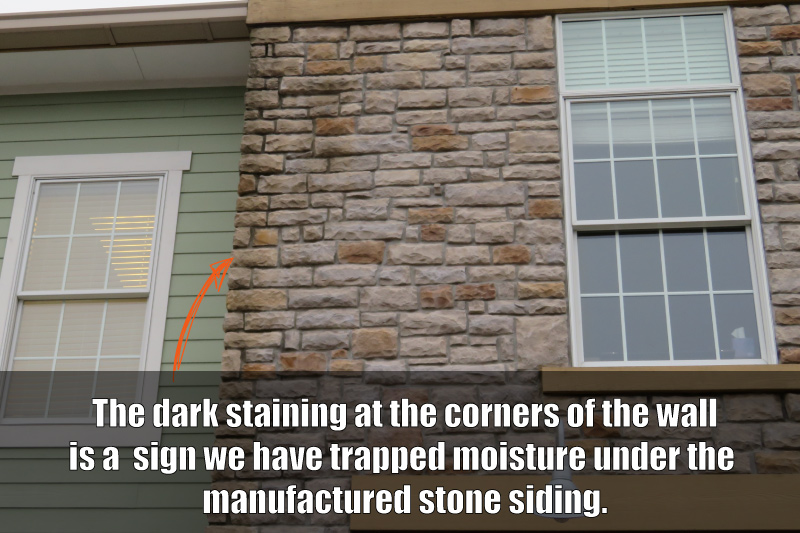

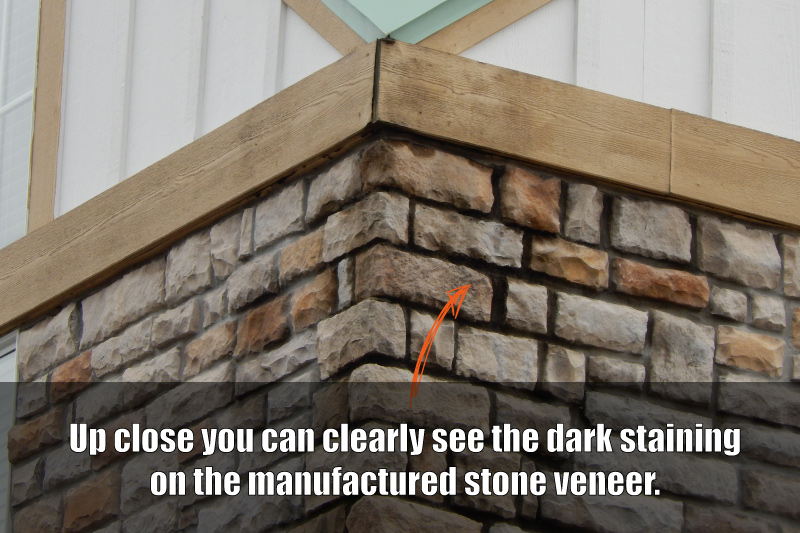

DARKENED ADHERED MANUFACTURED STONE WALLS MEAN BIG PROBLEMS

This is a good lesson for everyone. When manufactured stone siding soaks up moisture, it gets colder and darker- just like almost everything else in the world. Remember, adhered manufactured stone is NOT waterproof. If you notice dark staining on your home around the stone siding, it is a sign that you have trapped moisture under the surface and the wall assembly. All masonry sidings (real stone, stucco, brick, manufactured stone veneer) hold moisture to some extent. If the installer does a good job of decoupling the moisture-sensitive stuff like OSB sheathing behind the adhered manufactured stone, things don’t get wet and rot. But, if you have read any of my articles, you know that this isn’t happening.

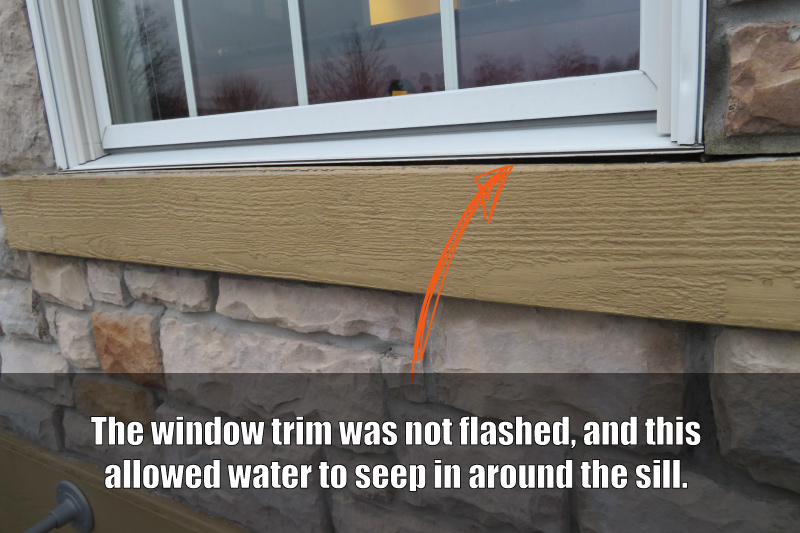

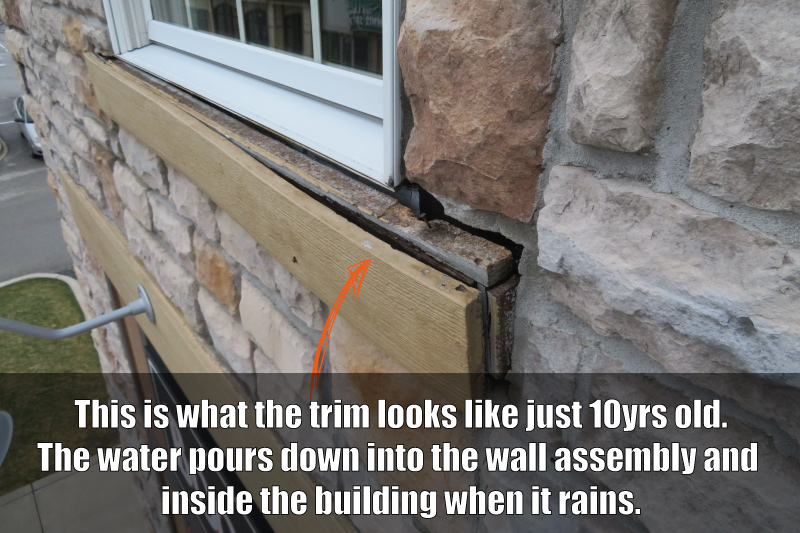

MISSING WINDOW FLASHING & SATURATED MANUFACTURED STONE

Windows are usually a big problem in adhered manufactured stone wall assemblies when it comes to leaking. Rain pelts the glass and vinyl of the window (both materials that do not absorb water) and hundreds of gallons of water run down the surface and land on the window sill below. If your installer did not detail the flashings around this window perfectly, the water will creep and wick in behind the stone veneer. When the installer makes no attempt at all to stop the water from getting in around the window sill it doesn’t take long for the moisture to wreak havoc.

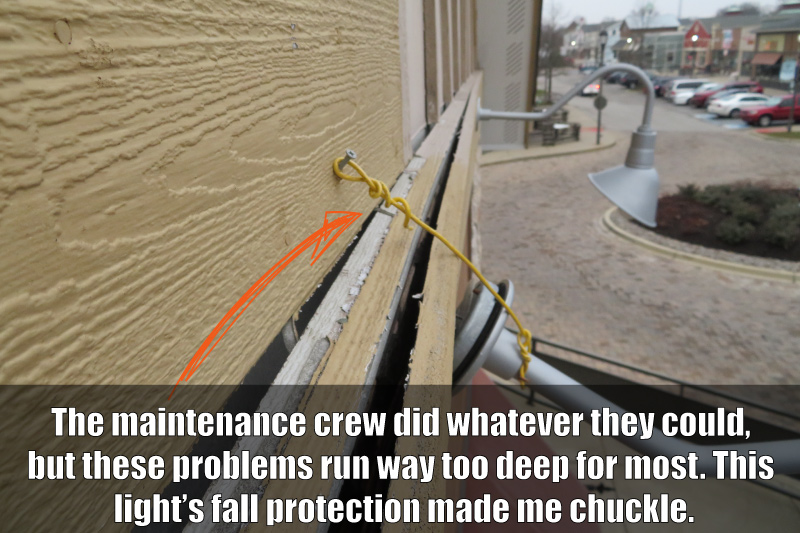

You can see the install of this complex was botched from day one. All the ‘installer’ did was screw a board to the face of the wall and slap the stone veneer up around it. That’s it. No flashing, no sealant, nothing. These guys have no idea what they are doing.

THERMAL IMAGING AND SATURATED MANUFACTURED STONE

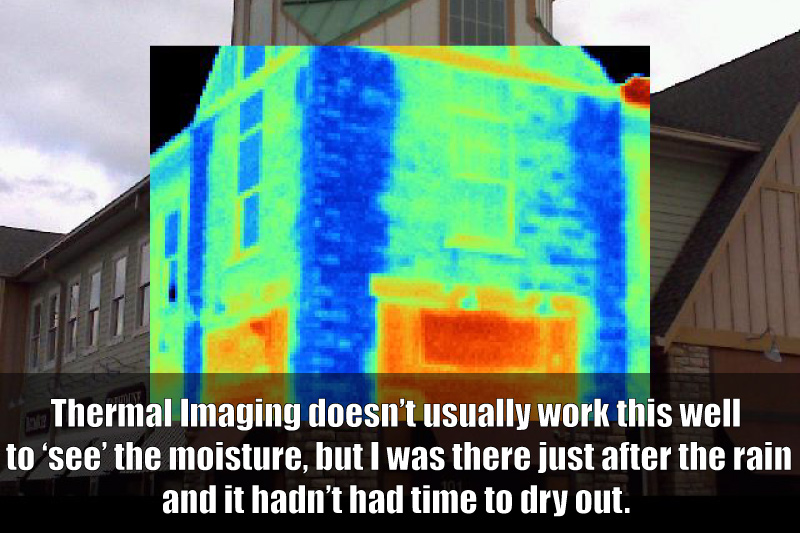

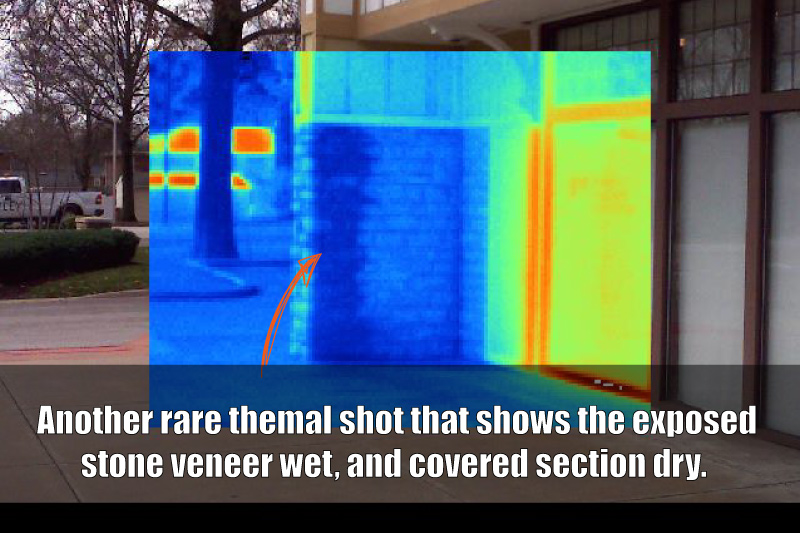

There is no denying that the use of thermal imaging (aka infrared) is a game changer in building science technology. However, I find it’s not much help during manufactured stone inspections, as the problems are typically much deeper into the wall assembly than the camera is able to detect. But there is always an exception…

This day was perfect for using thermal to ‘see’ what was happening. It had poured the night before, so everything was still really wet in spots. You can clearly see this in the colorful image below. This roofline is funneling the water right to the corners of the walls. Add in the fact that the manufactured stone was screwed up and that the frieze boards don’t even extend past the wall cladding, and you get a perfect storm of stupid design. This was doomed to fail from day one. How no one noticed any of these issues during construction is beyond my comprehension.

MOISTURE TESTING ADHERED MANUFACTURED STONE

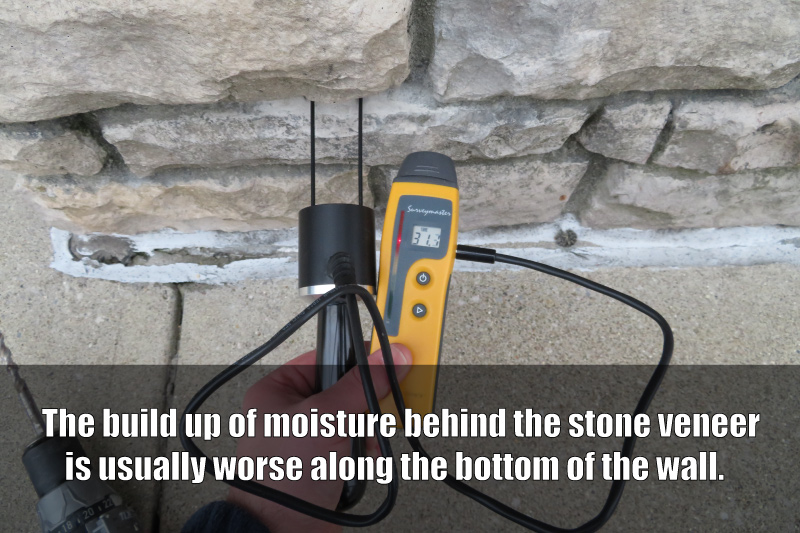

Drilling the manufactured stone for moisture testing can be tricky. It takes the perfect speed and pressure to not blow through mortar bed and the wood behind it. It’s even harder to do when the wall is wet and mushy behind the manufactured stone like a lot of them are. You must stop the drilling once you get into the plywood, but be deep enough you don’t hit the expanded lath behind the mortar bed. Doing so would give you a false reading with the moisture meter. It’s a balancing act that you must master in order to get accurate results with the testing.

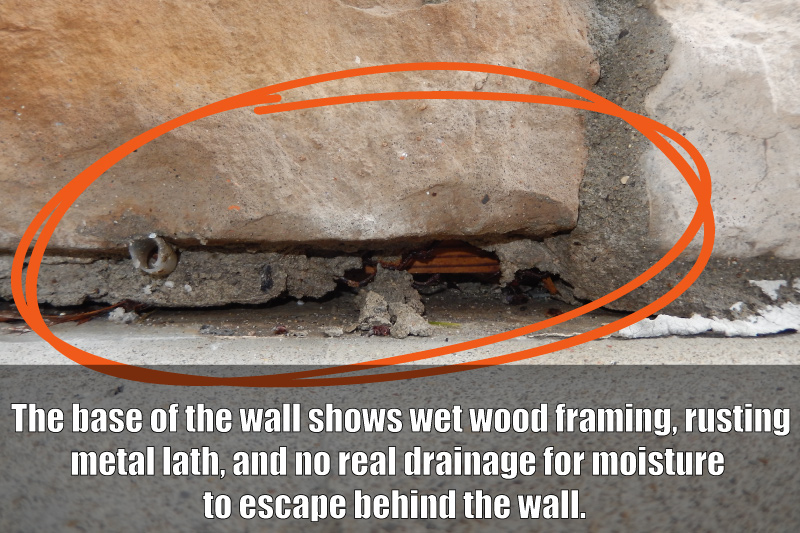

Along with all the missing flashing details on the upper sections of walls, the base of the wall is, of course, missing the proper drainage and weep screed. All of the water that is getting behind this manufactured stone has no way to get out–besides leaking into the shops throughout the complex.

So now you have a multi-million dollar shopping complex that is falling apart in just 10 years. The sad fact is that there is no saving it. At this point, you must rip the bandage off and correctly repair these buildings or they will continue to get much worse. The big question everyone asks is who will pay for all this? It will likely cost several million to repair, and I guarantee no one is jumping up and down screaming ‘pick me!’

For the rest of us who have bad days, and think the world is coming down on you, just remember, no matter how bad you think you have it, at least you aren’t the guy faced with this disaster.

I am a certified Moisture analyst and credentialed in the inspection of stucco claddings. Ben could not be more correct in his analysis. This product, MSV as it is called (manufactured stone veneer) is actually a stucco application and not stone. All the elements of this product is a stucco cladding and needs all of the same installation details as stucco. Since stucco is a becoming a lost art, installers have no business putting this product on the walls of any building with out a thorough understanding of the application of stucco and the science behind mortars. Like EIFS (exterior insulated finish system) it’s going to take the courts to put a stop to this construction negligence called MSV installation. Any home or building inspector should become very familiar with this product and the errors associated with its installation before they are paying for the repairs made. And as Ben so aptly pointed out in his article, it can be very expensive. DO NOT MISS this one. Good article Ben, keep up the good work. That makes you a great inspector…

Thanks for the kind words, Mike. I’ve got dozens of more stories to play show and tell with for the world to see. I just have to let the dust settle on the pending litigation. Stay tuned for more!

Ben are you saying adding manufactured stone veneer to the exterior of your home is not good? What is the proper way to install it? I live in central Florida, near the ocean.

Hi Jo – There is nothing inherently wrong with MSV; all the failures we see are due to human error during the installation. You’ll be fine if your contractor follows the proper documentation. Just understand that most do not do this.