James Hardie Siding Installation

Fiber cement siding has become one of the most popular products for exterior home use in the past thirty years. No brand is more popular than James Hardie regarding fiber cement siding, which estimates that over 8 million homes in the U.S. have its products installed James Hardie.

James Hardie Industries traces its origins to 1888 in Melbourne, Australia, when Scottish-born entrepreneur James Hardie emigrated and started a business importing oils and animal hides.

In 1917, James Hardie began developing and producing asbestos cement products, which became central to its business through much of the 20th century. By the 1970s, the health risks associated with asbestos led James Hardie to focus on developing and producing non-asbestos fiber cement products, which we now commonly call ‘Hardie Siding.’

What is James Hardie Siding?

James Hardie fiber cement siding combines cellulose fibers, Portland cement, silica sand, water, and additives into a slurry, which is then layered, compressed, and shaped into panels. The panels are cut, cured, and finished with textures, primer, or baked-on paint for durability and aesthetic appeal. This process results in a durable, low-maintenance product that resists weather, pests, and fire while offering versatile designs and long-lasting finishes. One of my favorite TV shows, How It’s Made, featured the manufacturing process for James Hardie in season 11, episode 8.

What sets James Hardie Siding apart from other siding materials, such as vinyl or wood, is its exceptional resilience to harsh weather conditions, fire, and pests. Unlike vinyl siding, which can warp or crack under extreme temperatures, or wood siding, which is susceptible to rot and termite damage, James Hardie Siding offers long-lasting performance with minimal maintenance.

James Hardie Siding Popularity

James Hardie products are found on nearly every new construction home I inspect with fiber cement siding. It is so common that it has become routine for folks to call ALL installation of fiber cement some version of James Hardie Siding. Even if the siding used on the home is not a James Hardie product, some of the more popular ones I hear are:

- HardiePlank

- HardieSiding

- HardieBoard

- Concrete Board (Hardie products are not made of concrete, but lots of folks still call it this)

It’s like saying that all cotton swabs are Q-tips or all tissues are Kleenex. However, I would like to point out that many other brands are available.

Many new neighborhoods in the past 20 years, like Norton Commons in Prospect, KY, are full of James Hardie siding installations-mostly Hardieplank lap siding. I have performed over fifty inspections in that neighborhood alone, and every home I have conducted a home inspection on has some details that do not follow the printed instructions in one way or another.

In other words, it’s constantly screwed up, one way or another.

Since Hardie®Plank is the most popular fiber cement siding available, we will use their documentation in this series. Just be sure and double check which product has been used on you home as there could be some minor differences to the installation guidelines.

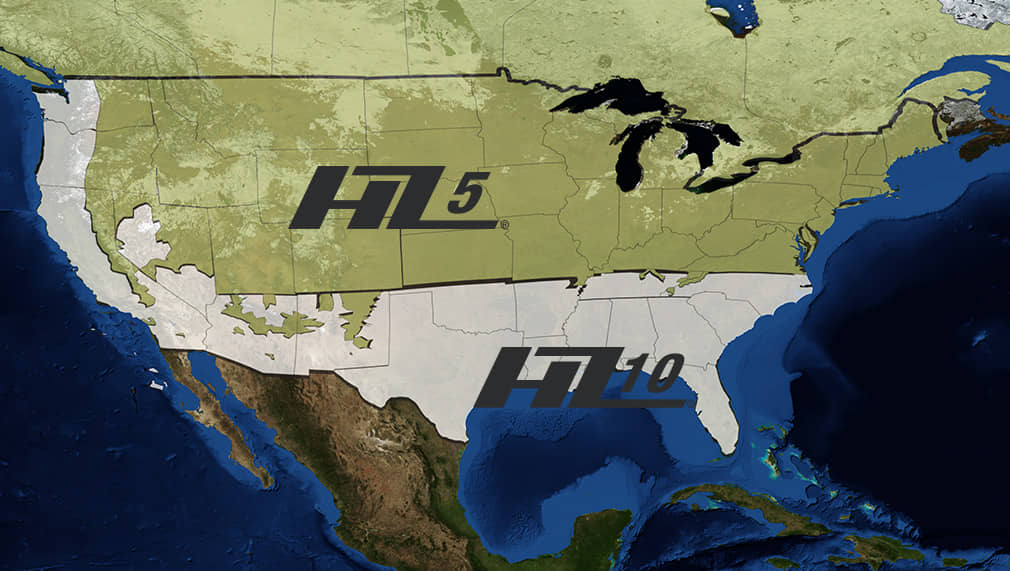

HardieZone – James Hardie Siding Installation

James Hardie provides products that are engineered for specific climate zones. The country is divided into two halves. It cuts the county in half on what seems to be the ‘snow line’. Mostly everything from Kentucky north is considered HZ5.

Although I must say, once you have survived a summer in Louisville, Kentucky, performing home inspections, you would argue that maybe they should notch that map and shift us ‘south’.

The below excerpts were taken from HardieZone.

Note: Based on my research, this two-climate zone system started around 2007-2008.

HZ5: The HZ5® product line is right at home in climates with freezing temperatures, extreme seasonal temperature variations, and snow and ice. To ensure its beauty matches its durability, we’ve engineered the surface for higher performance, giving it superior paint adhesion and moisture resistance. In addition, we’ve added a drip edge to provide improved water management. So you are not only getting an exterior that performs well in cold, nasty climates. You’re getting an exterior engineered just for it. (Download James Hardie HZ5 Installation Guide)

HZ10: Even when Mother Nature isn’t very motherly, the HZ10® product line delivers legendary James Hardie durability. This siding was engineered for areas with hurricane-force winds, salty sea air of the coast, and the brutal, humid heat of the Deep South. Engineered specifically for these climates, HZ10 boards resist cracking, splitting, rotting and swelling season after hot, humid, tropical storm season. (Download James Hardie HZ10 Installation Guide)

I did not see a huge difference between the two installation guides other than HZ10 does not ‘require’ the use of blocking with penetrations, and a few of the siding clearances are 2″ instead of 1″on the HZ5 zone. The James Hardie siding installation guide says blocking is ‘recommended’ for HZ10.

I don’t know why they require blocking for the country’s northern half and only recommend it for the southern half. But that is what they say. Someone will let me know if I missed any differences between the two guides.

It is also important to note that any home with a James Hardie products that does not follow the James Hardie siding installation may have their warranty void if the printed instructions are not followed. This is printed at the top of all Hardieplank installation guides.

BUILDING ENVELOPE PERFORMANCE AND MAY AFFECT WARRANTY COVERAGE. FAILURE TO COMPLY WITH ALL HEALTH AND SAFETY REGULATIONS WHEN CUTTING AND INSTALLING

THIS PRODUCT MAY RESULT IN PERSONAL INJURY.

HARDIEZONE.COM OR CALL 1-866-942-7343 (866-9-HARDIE)

James Hardie Siding Installation Instructions

James Hardie produces some of the best documentation in the world of building and construction. However, for many years, these instructions changed a lot.

I haven’t noticed any big changes over the last few updates, but about 13 different installation guides have been printed with changes to the ‘rules’ every few years.

The earliest James Hardie installation guide I have seen is from 1998.

One of the more difficult things to do as a home inspector is determining when a particular installation was completed. I can look at a house built in 2008 with Hardieplank installed, and the chances of the installation details being correct with modern James Hardie instructions are about zero. It’s even more complex/difficult on an old house that was remodeled at some point in time.

Does that make it wrong if the installation crew followed the available documentation to the letter 15 years ago?

It is complicated; you want things to be correct, but if ‘correcting’ an installation that is not showing any signs of a problem causes one to bleed money, folks are much less excited about it.

Below is a list of all the available printed James Hardie installation guides that I could find. If you have an older installation and would like a copy of the installation guide that should have been used during your siding installation, you can download it below. If I am missing one, please let me know, and I’ll add it to the list.

Although James Hardie does produce installation documents for each product, their ‘Best Practices Guide‘ is a much more detailed resource for installation details. This is the document that I use when writing my home inspection reports.

HZ5 Best Practices

You can download the best practice guide for the Northern Half of the states.

HZ10 Best Practices

You can download the best practice guide for the Southern half of the states.

Ben Hendricks

Hi, I’m Ben, and I inspect houses. I grew up with a hammer in my hand, and have been a professional home inspector for 15 years. My blog is here for info about home inspections around the Louisville, Kentucky area, and just about anything construction-related.