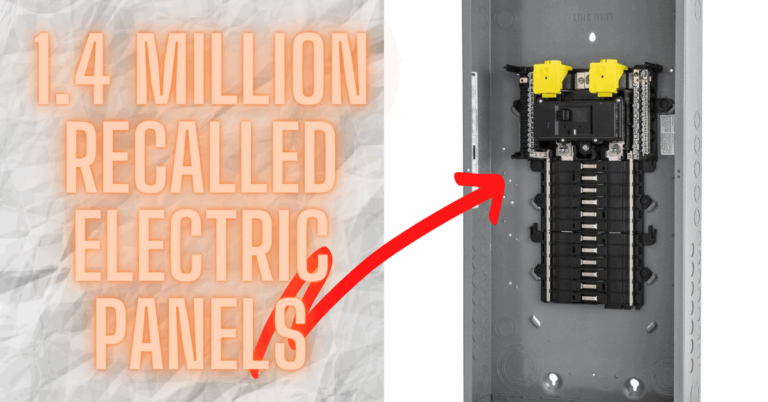

Square D Panel Recall: 1.4 Million Electrical Panels

Square D has recalled 1.4 million electric panels in June of 2022.

These panels were made from February of 2020 – January of 2022. If you have a Square D QO Panel made between those dates there is a good change yours fall under the recall.