Sealing My Ductwork With Aeroseal

Aeroseal takes HVAC performance to a new level with its method of air-sealing your ductwork from the inside.

Does it work? Is it worth your money?

Read my full review of Aeroseal here.

Aeroseal takes HVAC performance to a new level with its method of air-sealing your ductwork from the inside.

Does it work? Is it worth your money?

Read my full review of Aeroseal here.

Insulation, air movement, building science, blah-blah-blah. I know, most folks find it boring. But if you like saving money, and living in a comfortable house, stay with me here. One of the most common things I find at just about every home inspection in Louisville in Louisville is a poorly insulated attic scuttle hatch (that is…

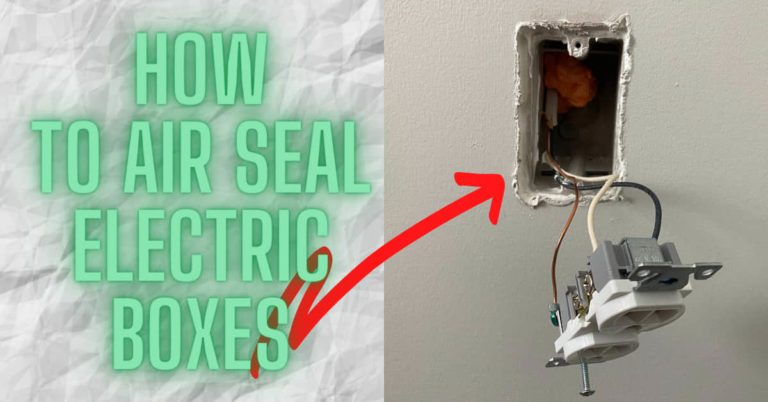

Air sealing your electrical outlets is one of the easiest things you can do to help lower your utility bills.

I’m a bit later than I wanted to be getting this written, but hey, better late than never. If you missed the first part of this post you can see it here: Best of Home Inspections 2014. So without further ado, the second half of the Best of the Worst pictures of 2014. A waterfall in…

Another year older, one or two more gray hairs found, and a stack of pictures to choose from. It’s hard to whittle it down to just a handful, but I selected the top 10 problems found during home inspections this year. A Cold Fireplace – This is a picture from a one year old home. The owners…

As a very hot summer comes to a close, heating your home may be the last thing on your mind. But with winter coming (for my fellow GOT fans) I’ve got some great news for you. There is a little known program available that can save you a lot of money. How does a 20% savings…