Aluminum Wire in Branch Circuits

When I’m performing a home inspection on a house built around 1970, I usually get the question, “Does it have aluminum wire?” Let’s talk about what the issue is, and what your options are if you are looking to buy a house that has aluminum branch wiring in it.

Branch Circuit Aluminum Wiring

Branch circuits are circuits that power the “small” stuff like your lights, outlets, and small machines (think dishwasher, disposal, etc.)

Aluminum wiring was first used as branch circuits around 1965 during a copper shortage and was used in homes until the mid-1970s. It’s the small 15 and 20 amp breakers in your electrical panel. The larger wires (usually 240v stuff) and the main power lines coming into the home are typically aluminum but do not have the same issues that the branch circuit wiring.

Why is Aluminum Wiring a Problem?

The Consumer Product Safety Commission (CPSC) released a “Repairing Aluminum Wiring” pamphlet that you can download here. Don’t be foolish and try to use it as a how-to guide. It’s meant to explain what can be done by an electrician who knows what he or she is doing. Here are some interesting facts for you:

- There are an estimated 2 million homes wired with aluminum wire.

- The problem is the connection points and splices at junction boxes, outlets, switches, etc.

- A national survey conducted by Franklin Research Institute for CPSC showed that homes built before 1972, and wired with aluminum, are 55 times more likely to have one or more wire connections at outlets reach “Fire Hazard Conditions” than homes wired with copper.

- On April 28, 1974, two people died in a home in Hampton Bays, N.Y. Fire officials determined that the fire was caused by an overheated aluminum wire connection at a wall receptacle.

When I find aluminum wiring, it seems I always get the question, “Do you think it will be a problem?” Another popular thing I hear is “If it hasn’t been an issue in 40 years, it probably won’t ever be one.” Wait….what? People downplay the issue in their minds because of the scope of the potential problem. It’s not convenient for them to have to deal with this right now. But it is real, and it can’t be ignored.

What are the problems with Aluminum Wiring?

Aluminum wiring has several unique traits that its copper counterpart does not. All of these add up to the reason it’s no longer used.

- Aluminum is Soft – When you tighten the set screw down on an outlet or switch, the aluminum wire will actually continue to flatten out a bit over time – even after you stop torquing the screw. This will cause a loose connection. Loose connections cause arcing. Arcing causes fires.

- Thermal Movement – Everything moves with temperature. Aluminum wire is no different. When the wire has electrical current flowing through it, it heats up. When it heats up it expands. The issue is that aluminum expands more than copper. Over time this swelling and shrinking can cause a loose connection. Again, arcing and fire.

- Oxidation – When the aluminum wire is exposed to oxygen it oxidizes. This byproduct is called aluminum oxide. This stuff can deteriorate the connection.

- Corrosion – When moisture is added to the mix of aluminum wire, you get galvanic corrosion at the connections.

I Have Aluminum Wiring in My Home!

The first thing you do is get an electrician experienced with aluminum wiring to come check every connection they can possibly get to in the house. Will they be able to check them all? Doubtful. Most houses have junctions behind drywall or in the attic we can’t see or know they are even there. According to the rules, there should never be concealed junctions, but the reality is that people don’t always obey the rules. Having ol’ sparky come check things out can be pricey, but his house call is much cheaper than a house fire.

What can be done to minimize the risk of aluminum wiring?

There are several products on the market designed to help minimize the risk when dealing with aluminum wiring.

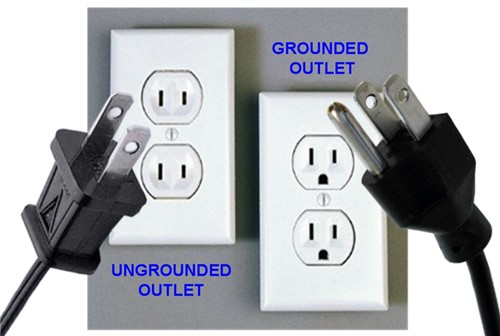

1. One of the more popular products I find people know something about are the specially rated outlets and switches made for aluminum and copper wires. These are marked with a CO/ALR on them. CO=copper – ALR=Aluminum. Would you know to get these for your house if you had aluminum wire?

Here is a scenario for you:

Being the hip, young couple that you are, you’re ready to tackle some DIYing this Saturday. So your normal Friday movie date is replaced with a shopping trip to Lowe’s. You get your paint, brushes, tape, flooring and so on. Your better half proclaims those ugly almond outlets have got to go in lieu of some nice new white ones. No worries, right?

You stroll to the electrical aisle and reach for those shiny white outlets. You need 5 for the living room. Better get 6, just in case. How much? $.68 cents. No sweat.

You grab your 6 outlets and start to walk away. Out of the corner of your eye you see another receptacle that looks identical to the one in your hand, except it’s almost $4 bucks. What? $4 for one! I don’t think so. Let’s roll babe.

2. There are special connectors called AlumiConn available. These are approved by the CPSC, but at nearly $4 each, they are not a cheap option. Understand that is $4 per wire; per connection.

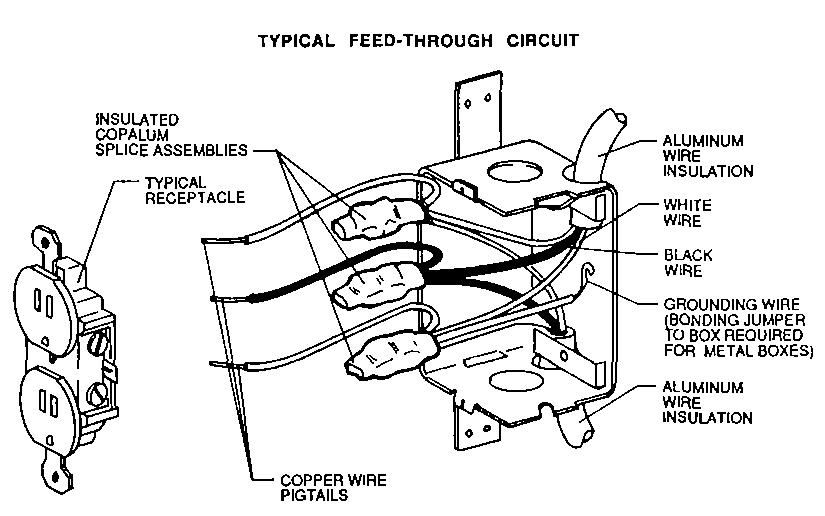

3. Another product is the COPALUM connector. This system uses a special clamp, crimping tool, and heat-shrink to create a copper pigtail off the aluminum wiring. You must be certified to use this system. Some areas don’t have anyone available who is certified in using the COPALUM system.

4. Total Replacement of the aluminum wire itself. This is, of course, the safest of all options. It is also the most expensive. Cost will vary, as every house is different in the process used to replace the wire. You’ll need to speak with an electrician to get an idea of what you can expect. Keep in mind this is typically thousands of dollars. It’s not a cheap process.

If you have aluminum wiring in your home, you need to get that electrician out there ASAP. If you are not sure if you have aluminum wiring or not, a reputable home inspector in your area should be able to come out and take a look for you. You shouldn’t take the cover off of your electrical panel yourself unless you know what you are doing. There are things in there that will kill you.

You have options in what can do. You can repair or replace. Either is better than nothing at all. And when it comes to situations like this; it’s never a problem until it becomes one.

Good post nice to read.

If you weee considering buying a condo and it had aluminum wiring would you pass and look for something else?

Probably, but that would be your call to make. One thing to consider- even if you do everything right with your unit, you can’t control what the neighboring folks do (have they done everything the proper way to mitigate the danger). Also, be sure and check with your insurance company. I’m hearing lots of them are charging more for homes with aluminum wiring. In some cases, a few are flat out denying coverage. Good Luck Dan. Let me know if I can help in any way.

We’re buying a 1970 home in CA. The seller reports that all the wiring was replaced with copper in 2015; our home inspector said there’s still aluminum at the breaker box. Why wouldn’t that have been replaced, and should it be? The seller’s electrician says the “breakers are rated for aluminum” and “local and national codes for bid splice work inside the main distribution panel and therefore pig tailing in this application is unnecessary and against code. No further action is required.” We’re confused. Was our inspector wrong?

Hi Karen – You’ve got a lot going on here. My best advice to you is to hire your own electrician and have them check thing out at the house. Do not rely on the sellers (or their agents) electrician who may be pencil whipping things to keep the people who are referring them happy. Also, be sure your electrician is familiar with aluminum wiring and how to handle it. Not every electrician knows the rules. I’ve had many clients who are younger electricians and admitted to never work with it. Good luck and let me know how it turns out!

Should I call an electrician or do it myself? I got the same problem with our kitchen outlet and my mom has no idea as well of what to do.

Call an electrician who is old enough to have lived through the aluminum wiring phase. Younger guys (or gals) who are just starting out may not have the knowledge to properly repair things for your safety.

I’m inquiring about if all of my light fixtures needed to be fitted with alumiconns as well as all of my outlets and switches?

Hey Sean, that is the deal. Every connection needs to be addressed and repaired. One of the biggest problems with this method is sometimes you don’t know about a buried junction box or you don’t get every connection done. At that point, your electrical system is only as good as the weakest link.

My home in FL was built in 1969 (my wife and I bought it in 2003)and originally had 100amp fuse panel with aluminum wiring. The panel and wiring was upgraded in 1982 to a 100amp breaker panel and copper wire. I really never had a reason to open up the panel until this Thanksgiving when the 2nd oven we bought decided to let’s say take a permanent vacation. A little background on me. I work with pumping stations that use 240v single phase up to 480v 3 phase. From the main exit off to our panels we only use copper, aluminum has the habit of creeping under heavy loads. Any way. Before we went to go buy yet another oven I decided to check voltage and amp draw at the outlet and breaker. (I DO NOT ADVISE ATTEMPING THIS ON YOUR OWN UNLESS YOU HAVE THE TRAINING AND EXPERIENCE TO SAFELY DO SO) Voltage 125/123 on each leg (normal for or area) and amps 10/9 on each leg under load a bit low compared to the owners manual starting avg amp draw 25-30amps. After opening the panel cover to check voltage and amps at the breaker I find a 50amp (that oven requires a 35amp max) breaker with aluminum stranded wire. Wife decided she still wants a new oven so I will be replacing outlet, box, wire to copper 8/2 and new 40amp breaker to meet the requirements of the new oven. What I don’t understand is if you upgrade the panel and the rest of the wiring in the house, why in hell would you not do the oven line as well? Can it be used safely yes it can but come on dude! It’s the easiest line in the entire house to rerun!

Hey Martin,

I believe the key element to your story is the stranded aluminum wire used for the range- not single strand solid aluminum wire. We still use stranded aluminum conductors today for many service lines and 240v circuits in residential construction. This style of wiring never had the problems that its solid core counterpart did. Good on you for checking things over before installing the new range!

Great article, very informative and clearly explained. Thank you!